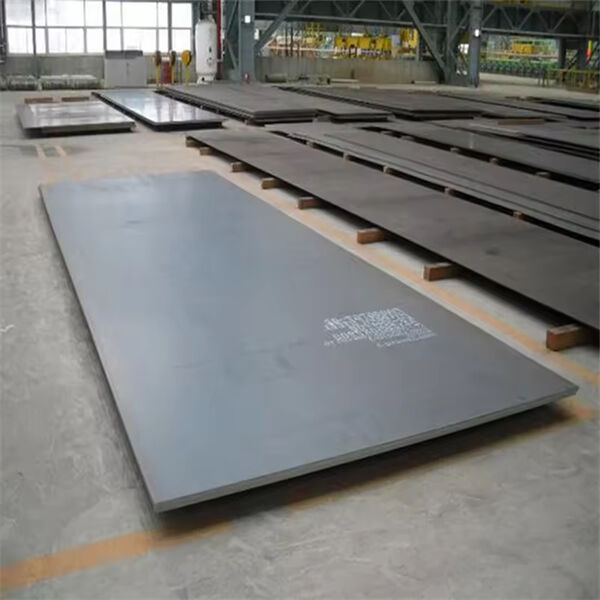

The cold rolled stainless steel sheet is one of the most robust materials and can be used for many different operations. The good thing about it is that you will not experience any rusting meaning it can be used outdoors or in damp environments and last for ages. This is a type of cold rolled stainless steel sheet that are high quality and can be used in numerous layouts, which makes them one of the most favored choices for most projects; by ROGO.

The great thing about cold rolled stainless steel sheet is that it is very strong, the same as ROGO's colored aluminum coil. Therefore, it has the capacity to withhold a good amount of weight and pressure without getting damaged. When developers use this material they know its structural integrity will allow it to stand tall and strong, regardless of the weather elements such as high winds and tropical rainstorms. That kind of strength is crucial in construction and other projects that put a premium on safety.

Cold rolled stainless steel sheet has yet another advantage and it does not detractor from subsequent exposure to water or other liquids. This is vitally important when it comes to outdoor applications where rain or snow can fall on the surface This corrosion-resistance means that stainless steel sheets can be used in outdoor settings and can be quite predictable, requiring few to zero backups since there is very little maintenance.

Cold rolled stainless steel sheet also has aesthetic advantages, identical to coated aluminium coil produced by ROGO. Moreover, it beautiful thanks to the smooth, shiny finish. The stylish look of this tile makes it ideal for a range of decorative applications in homes and commercial properties. In modern kitchens, for example; and fashionable offices where elegance, and sophistication can be seen.

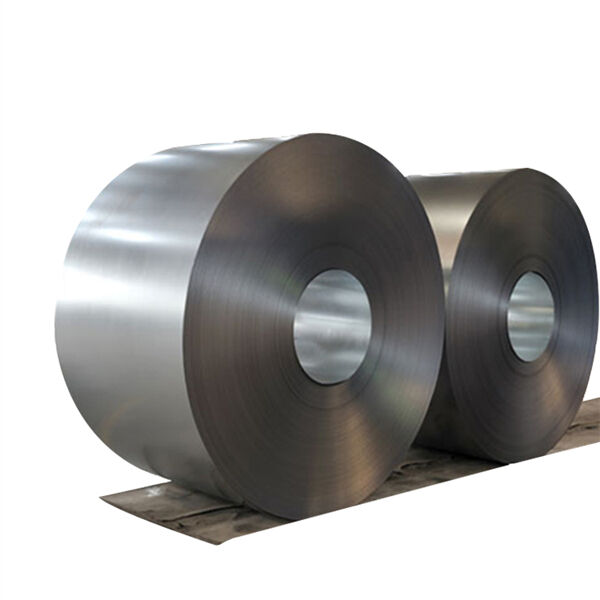

Cold rolling is the production process that astm 304 stainless steel cold rolled sheet is produced, similar to the ROGO's product like hot dipped steel coil. The cold rolling mills operates at a low temperature and hence the steel is passed through rollers. Using this method is great to make the max strength and toughness of steel and so it can be applied in variety of ways. Precise size and Shape: It can be suitable types of steel as per their requirement in applications because cold rolling offers more exact shapes and sizes.

Cold rolled stainless steel sheet the most common applications is appliance, same with the black aluminum trim coil built by ROGO. It is found in numerous everyday items such as refrigerators, stoves, dishwashers and microwaves. This makes it ideal for these types of appliances as they tend to have drinks-mishaps on them and in an environment with increased humidity, this sensor can avoid any internal damage.

Cold rolled stainless steel sheet is also widely used in construction, decoration and other fields, identical to ROGO's product bobinas de zincalum. Automotive parts: Some Stainless Steel Sheets and Plates are mainly for car.

an export oriented enterprise, ROGOSTEEL has focused over last decade on enhancing the quality of its products promoting services. Through efforts of all staff members, ROGOSTEEL have built cooperative relationship with nearly 500 customers from 100 countries in Asia, Europe, South Cold rolled stainless steel sheet, Oceania and Africa has earned a strong reputation their honesty and pragmatic method of operation.In 2014, business has passed ISO9001 quality and management system certification with KS certification. Additionally, it has SGS and BV testing certificates, and has been awarded "Shanghai's Most Export-oriented Enterprise", "China Inspection-Free Products" and "Alibaba Excellent Trade" for many consecutive years Businessmen". The customer satisfaction rate is 100%.

Rogosteel has nine production lines that have an annual output 2,000,000 tons has made long-term strategic agreements with more than 20 professional logistics companies major national port customs brokers to ensure the Cold rolled stainless steel sheetof shipping cargo. are able to assist customers process various certificates testing and certificates in customs clearance document for goods delivery. includes the BV certificate, CO Embassy certification, and so on.highly skilled team of after-sales experts is available 24 hours per day oversee the service. Within 12 hours, the company will take care of any after-sales problems offer solutions within 24 hours.

Rogosteel provide a wide Cold rolled stainless steel sheet products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. We offer custom-designed services. Colors from RAL well as custom-designed colors for customers are available. is a broad range uses and is suited corrugated board/glazed tiles/sandwich panel/home appliances/power distribution cabinets keels.Relevant instances include the towns located in Eastern Europe, large domestic airports, Samsung factories in South Korea, Hisense refrigerators in Africa, government engineering procurement as well as port construction projects within the Middle East.

Rogosteel a product that has been certified by SGS/BV. ISO9001, ISO14001, OHSAS18001, OHSAS18001 ISO14001 quality management systems. raw materials product substrates are sourced from Tangshan Iron and Steel and HBIS. The paints for the product are made by internationally-renowned brands like AKZO and PPG. technology behind the product utilizes high-end manufacturing equipment that is imported from Cold rolled stainless steel sheet. facility also has fully enclosed production workshops and rigorous quality control. The production line is overseen by a expertsthe field of quality inspectors in real-time. The product that is produced is tested at 100%.have a variety of instruments, including: board flattening equipment, defect detectors and ultraviolet resistance testing devices. Warranty for 15 years.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy