Preface: Hi there! And today, we will talk about something very much necessary to make a product: which is CR coil. No worries, if you have no idea what that is yet; we will explain everything neatly and easy so everybody can follow along. Have you ever wondered how things are made, such as the cars we drive or the buildings we see? There are many steps and lot of hard work undertaken in order to process the raw materials into useful products which we use every day. Steel is just one of the materials involved in the creation of many of these products. ROGO cr sheet a tough metal which we use to make many things that you know of around your house, like the skeleton of your house, all those utensils with which you eat food and some play equipment too. The truth is, many of the things that we rely on in our world to be strong or safe would not exist without steel.

What's the Difference? Steel appears in a myriad of shapes, but today we will look at one type known as CR coil. The acronym “CR” is for “cold-rolled. So that means that the steel has been skinned, and then flattened and dropped in temperature. CR coil through this process, made in more tough and also easy to shape different types of items. Another variety of steel, known as "HR coil" which means "hot-rolled. For HR coil :Steel is heated and rolled into shape. But HR coil may not be as stiff or accurate like CR coil due to which in important product form the manufacturers use CR coil.

CR Coil Applications in Manufacture: Then, which industries could you see CR coil impacting? The fact on the opposite hand is having in your immediate surroundings! CR coil is used for construction materials to create structures like houses and other important things like cars, refrigerator, microwave, computers, TVs etc. Even ROGO gi coil price until it will be cut, shape and other dimension so they are able to use it in many kind of steel product Its landing strip quality means that there are many different things you can do or form CR coil into.

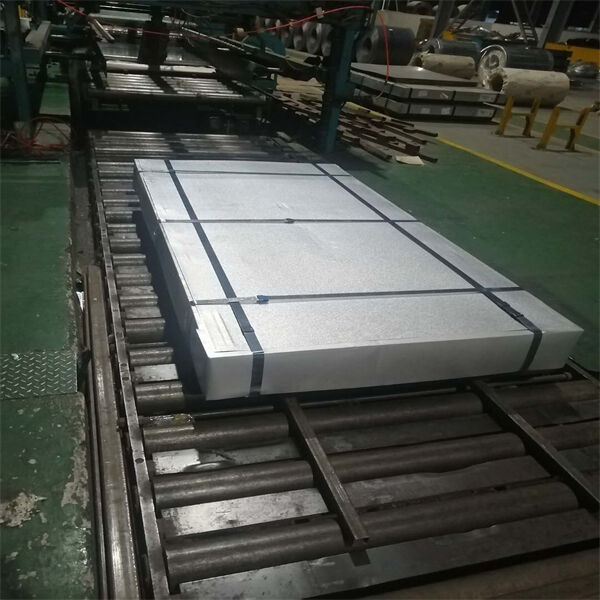

Before CR Coil: Raw Steel to CR Coil It begins with raw steel, which is carved into massive metal blanks. This raw steel is finally passed through a range of cold steel machines to give the final shape in CR coil shape. This involves cleaning of the steel so that any dirt is removed, cutting it into required size and then out rolling it with heat applied to cool it down. Metal is turned into a flat sheet of Steel and can be stored away until it is required for various products. It is then formed to the desired shapes and sizes for each product.

Pros and cons of CR Coil — The first question that might come to your mind is why CR coil is so much famous in manufacturing. Strength: One reason is that it is very strong, so can take a lot of abuse and remain in good condition. We highly durable Qsteel CR coil products, your can depend on our steel to keep on performing. ROGO gi sheet coils is also very accurate, and thus gives manufacturers the ability to manufacture exact sized product as per specifications. And also, it can be painted and coated with ease thanks to its smooth surface that helps prevent both rust and minor damage. But before you think the CR coil is the answer, there are also some caveats to using it. For example, it is less malleable than other materials to be curved into round shapes. In addition to potential bends, CR coil may come at a higher price than some other forms of steel, so manufacturers need to take that into account when evaluating what materials to employ.

an export oriented enterprise, ROGOSTEEL has focused over past decade on enhancing quality its products and improving service. ROGOSTEEL has built a cooperative relationship with more than 500 customers across Asia, Europe and South America. ROGOSTEEL also enjoys an enviable reputation for their practical Cr coiland integrity.The company was awarded the "Shanghai Best Export Enterprise" and China Inspection-Free Products", and "Alibaba Outstanding Trade" over a period time. Customer's satisfaction reaches 100%.

Rogosteel provide wide range of products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. Offer customized services: 1825 RAL colors customer-customized colors offered.It can be used a variety of applications. It ideal for corrugated board/glazed tiles/Cr coilpanel/home appliances/power distribution cabinets keels.Examples relevant cases include the building of port facilities in the Middle East, government engineering procurement, and major airports located in Eastern Europe.

Rogosteel has nine production lines, with annual output of 2,000,000 tons. has also developed long-term strategic partnerships more than twenty professional logistic agents as well as major national port customs brokers guarantee the effectiveness of cargo shipping. According to Cr coilpolicies can collaborate with the processing of various tests certification certificates in customs clearance documents goods delivery, including BV certification, CO embassy certification, etc. team of experienced after-sales specialists is on hand all hours of day to ensure service is being monitored. Within 12 hours, the business will be able to respond to any post-sales issues provide preliminary solutions within 24 hours.

Rogosteel has successfully completed ISO9001 Quality Management System, ISO14001 environmental management system, OHSAS18001 occupational health management system, SGS/BV as well as other certifications. The raw materials used for the product substrates originate from Tangshan Iron and Steel and HBIS. paints used in the Cr coilprocess made by internationally renowned brands such as AKZO and PPG. production process based on high-end production machines that are imported from Germany. It also features fully enclosed production areas and strict quality control. aspects of the production line are monitored 24/7 every day. The skilled quality inspection team is monitoring production in real-time. The finished product is tested with 100% accuracy..carry a variety of equipment, including board flattening equipment, defect detectors and ultraviolet resistance testing equipment. Warranty period of 15 years.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy