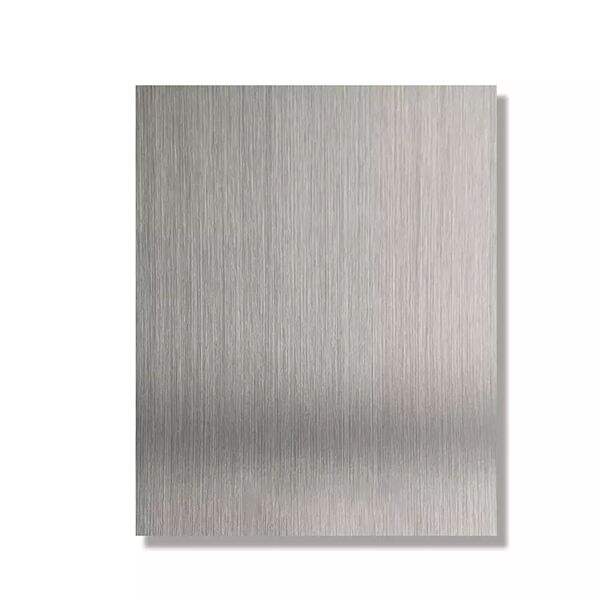

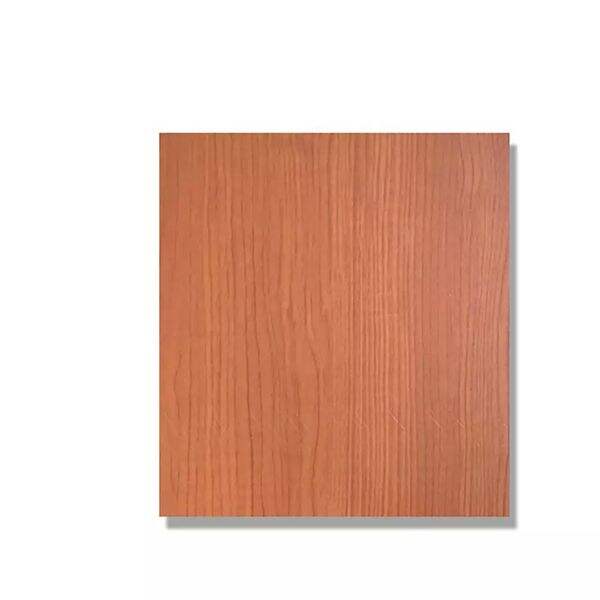

Coil sheet steel is a highly useful product that can be found in a lot of applications. This is strong, lasts a long time, and is excellent for constructing items like homes, automobiles, and aircraft. In this clip, discover more about gi coil sheet and the processes behind its production.

Coil sheet steel is produced by rolling large rolls of steel, which are then flattened into thin steel sheets. And these can be snipped into smaller bits or formed into all kinds of shapes. Coil sheet steel is extremely durable and also malleable. This makes it ideal for construction and manufacturing.

The raw materials such as iron ore and coal, are used to produce ppgi coil sheet. These materials are then melted in a furnace to yield molten steel. This molten steel is poured into a device known as a caster, which shapes it into a long, thin slab. The coil of slab is rolled and cooled, then sized into sheets. Those sheets go on to become buildings, bridges and machines.

Coil sheet steel is beneficial for construction and manufacturing in so many ways. The main advantage is that it is very strong and it is durable. It is also very versatile, so it can be used in numerous ways. It is easy to work with coil sheet steel and form whatever it is that is needed. That makes it a perfect material for building cars, trucks, airplanes and buildings.

The coil sheet steel is of various grades and types, which means there are different type uses of them. Certain species of it are extraordinarily robust εnd used in bridges and skyscrapers. Other varieties are more pliable and are found in automobiles and appliances. The use of coil sheet steel is determined by what it is for and what level of strength it requires.

The environment benefits as well — coil sheet steel is 100% recyclable. It can be recycled and reused, without losing strength. We can help keep waste down and our planet safe for future generations by utilizing coil sheet metal.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy