You heard about the alu coil. Serious Structure Stuff: Sure, it's a funny word but when you're building and making things IRL it plays a vital role. An alu coil is a long, thin and tightly wound piece of aluminum. This might not sound like much, but as it happens aluminium is a very useful and powerful material - so if you have an alu coil, that's something!

Because aluminum has many desirable properties, it is commonly used in construction and manufacturing. This, the first reason that it is lightness and not contribute much to weigh on structures such as buildings or vehicles. In that the next case, Aluminum is lightweight, but it remains quite sturdy and due to this feature uses ) One of product line up such as maintain its form during stress circumstances. Lastly, Aluminum is corrosion-free and can withstand outdoor uses for a long period. For example, you can see alu coil used to create gutters that keep water from running over the edge of a roof and falling straight down -- protecting both your lawn and basement at home; roofs that cover homes all across our country; even parts for airplanes so they may soar high in the sky! One of the nicest things about aluminum is that it can be formed into an arrays or shapes and sizes to suit any purpose.

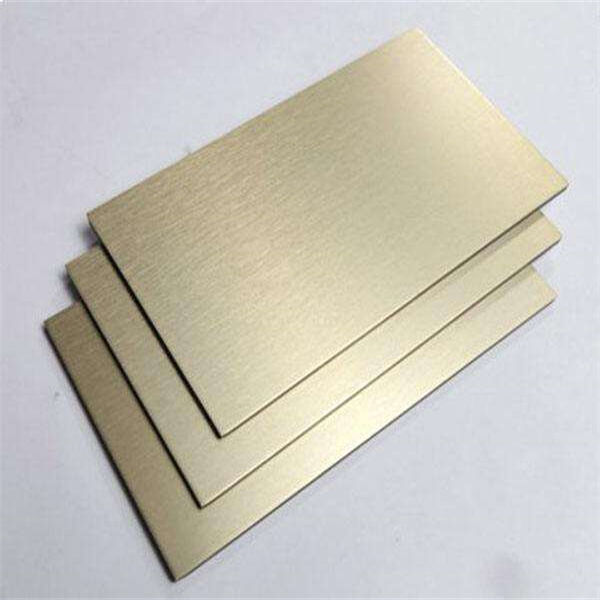

So Today we will learn how to make alu coil. When an alu coil is made, the aluminum heats until it turns into a liquid. The liquid aluminum is then rolled out onto large flat sheets once it has melted. They then cut the sheets into long, narrow strips and roll them into compact coils. In some instances the coils can change in size, or become thicker if a larger weight class is required. From here the coil can be shipped off to factories or construction sites where they are then used for a variety of products.

Aluminum coils are one of the premium ingredient that can be used for different purposes in construction as well as manufacturing and their various benefits make it a viable option. It is a good quality of aluminum like strong and light, so it will not get too heavy when constructing buildings or structures in various ways. It is also rust-free so it will be as good as new for a long time, not requiring much maintenance. This is particularly vital for things subjected to the elements, as they must be strong. On top of this, aluminum is a sustatinable material and thereby for every time it will be use, waste shall also decrease as well protecting our natural resources. It is eco-friendly and good for the environment because it has low-impact on nature, which makes aluminum awesome for builders and manufacturers that give a shit about our planet.

So when working with aluminum coils, it's absolutely essential to get the appropriate type of protection for your specific piece. It contains protection to preventa aluminum from rusting and corroding polver time. Aluminum can be covered with various types of surface treatments, but many are not durable enough for wide application. An anodizing process and painting/powder coating can also make provide the surface last longer. Each might be appreciated if course of treatment is considered for particular project and situation.

The aluminum coils are part of the Lean material and to have them last for long, you can follow these tips. Step one is to select the perfect kind of coverage for yourself Should do wonders on aluminium to keep it away from harm. Do not touch the coil when you're handling and installing it. Do not hit or scratch it, dents and scratches can cause rusty problems etc. Finally, make sure to check the coil periodically and maintain it because you can have some issues in time that are better solved earlier than later on.

As an enterprise that geared towards exports, ROGOSTEEL has focused over last 10 years on enhancing the quality of product promoting services. ROGOSTEEL has developed collaborative partnership with more than 500 clients in Asia, Europe and South America. The company also has alu coila reputation their pragmatic approach and honesty.company was awarded "Shanghai Best Export Enterprise", China Inspection-Free Products" "Alibaba Outstanding Trade" for several years in a row. The satisfaction of customers is 100%..

Rogosteel has nine production lines with an annual output 2,000,000 tons and has made long-term strategic agreements with more than 20 expert logistics agents major domestic customs brokers for ports to ensure the effectiveness shipping cargo. We are able to work with our customers process various testing certificates and certification the document of customs clearance to ensure the delivery their goods. includes the BV certificate, CO Embassy certification, more.company has a professional after-sales alu coilthat monitors the after-sales process throughout the process. They are available 24 hours a day. Within 12 hours, the business will respond to any after-sales problems and offer solutions within 24 hours.

Rogosteel provide wide range of products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled and aluminum coil. Offer customized services: 1825 RAL colors and customer-customized colors are available.It is ideal for wide range uses such corrugated board/glazed tiles/sandwich panel, home appliances/power supply alu coil/keels.Examples of relevant cases include development port facilities in the Middle East, government engineering procurement large airports located Eastern Europe.

Rogosteel has been certified by the ISO9001 Quality Management System, ISO14001 environmental management system OHSAS18001 occupational health management system, SGS/BV and other certifications. raw materials of the product substrates come from Tangshan Iron and Steel and HBIS, and the product paints come from internationally renowned brands like AKZO and PPG. The technology behind product utilizes high-end manufacturing equipment that is imported from Germany. facility also has an alu coilproduction workshop strict quality controls. Every aspect the production line are monitored 24/7 every day. expert quality inspection team oversees production real-time. The success rate of the final product testing is 100%.We stock a wide range of instruments, including board flattening equipment, defect detectors, as well as ultraviolet resistance testing equipment. Warranty of 15-years.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy