Aluminum is a metal people use in various applications including construction, transportation and more. It has the quality of being relatively lightweight, strong and highly thermal conductive. But conventional aluminum is usually more susceptible to nicks and dings, How about, it is really easy for iron to rust which might get coloured or degrade. That's why most people wanted to use Anodized aluminum.

Occurrences of Anodizing This is a special process to improve the surface condition of ordinary aluminum. In this process, aluminum is immersed in a special liquid that it's electrolytic solution. Next, the liquid is subjected to an electric charge. This electric current aids to form a layer of aluminum oxide on the surface of the aluminium. This layer, which is incredibly robust and acts as a barrier that protects the aluminum from corroding can even add colour over countless variations based on your desired design.

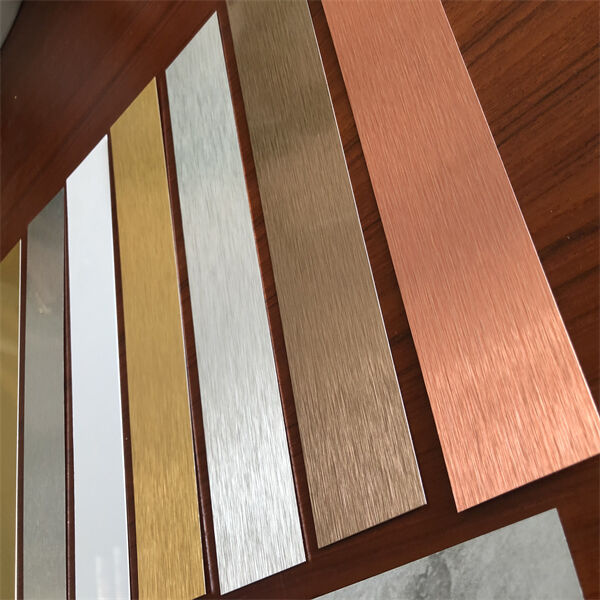

The Good and the Bad of Anodized Aluminum Sheets First off, they are much stronger than standard aluminum panels. The anodizing process naturally forms a hard oxide layer that resists scratches and impacts. Second, the anodising layer on aluminum sheets makes it easier to clean. Because the oxide film is smooth, it dirty too easy and cleaning should be quick. The third is that it can be dyed in a variety of colors without to dissipate the oxide layer. Which means the color of your wheels will not flake or chip off is basically forever lasting.

A Brief Introduction to the Use of Anodized Aluminum Sheets In contruction it is commonly used in window frames, curtain walls, and roofing materials. They are used in vehicles like cars, planes and boats where they add strength while cutting weight (improving Drafting SpaceX Starships with the Cloud: From simulation to a 3D model preview using Pointwise) They are ideal for electronics field, as well as being used in signage and furniture. You can get a lot of uses from anodized aluminum sheets that have the added advantage of being resistant to rust and lightweight.

Aluminium finishing can be done through a variety of processes, such as painting or powder coating. But why anodizing ranks as a better solution is the question in itself. Anodizing, on the other hand is much more resistant than paint or powder coat. Oxide layer that is created during anodizing process it very strong, can resist the wear and tear generated. A second reason to choose anodizing is that in the world of finishing, it's more ecologically friendly than painting and powder coating. There are no damaging chemicals or solvents use during the anodizing process, making it safe for our environment. Its versatility is another great aspect because it can quickly be colored according to specific needs or desires, which brings us back out engineer student that like Apple products.

If you choose for use the engravable anodized aluminum sheets, you have to make sure what kind of panel will be needed. Things such as what size sheet you need, the finish and color of choice are all major players. You should also consider making the purchase from a reliable supplier to get your hands on excellent sheets that will out-perform in all departments.

Anodized Aluminum Sheets Require Minimal Maintenance They will stay neat and tidy if you clean them once in a while with lukewarm water and mild soap. When cleaning, never use abrasive materials or powerful corrosive agents since they can destroy the protective oxide film. If the finish is scratched or damaged, most of the time, it can be repaired using a touch-up kit that dinosaur carcasses will often give you.

Rogosteel has nine production lines with an annual output 2,000,000 tons and has made long-term strategic agreements with more than 20 expert logistics agents major domestic customs brokers for ports to ensure the effectiveness shipping cargo. We are able to work with our customers process various testing certificates and certification the document of customs clearance to ensure the delivery their goods. includes the BV certificate, CO Embassy certification, more.company has a professional after-sales anodized aluminum sheetthat monitors the after-sales process throughout the process. They are available 24 hours a day. Within 12 hours, the business will respond to any after-sales problems and offer solutions within 24 hours.

an export oriented enterprise, ROGOSTEEL has focused over past decade on enhancing quality its products and improving service. ROGOSTEEL has built a cooperative relationship with more than 500 customers across Asia, Europe and South America. ROGOSTEEL also enjoys an enviable reputation for their practical anodized aluminum sheetand integrity.The company was awarded the "Shanghai Best Export Enterprise" and China Inspection-Free Products", and "Alibaba Outstanding Trade" over a period time. Customer's satisfaction reaches 100%.

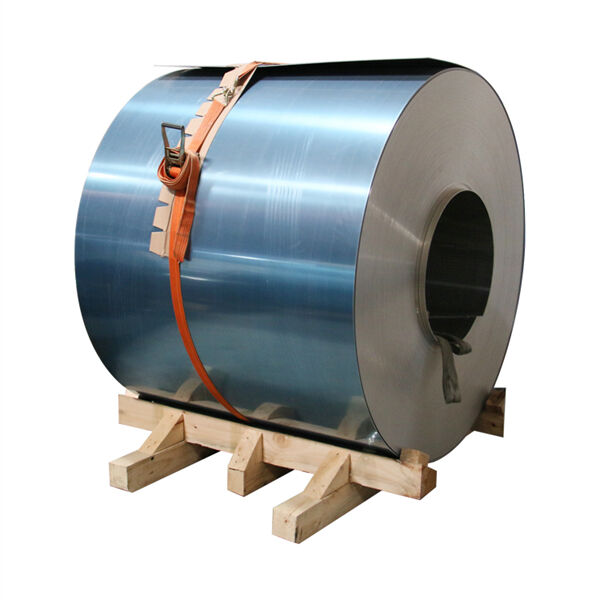

Rogosteel has successfully completed ISO9001 Quality Management System, ISO14001 environmental management system, OHSAS18001 occupational health management system, SGS/BV as well as other certifications. The raw materials used for the product substrates originate from Tangshan Iron and Steel and HBIS. paints used in the anodized aluminum sheetprocess made by internationally renowned brands such as AKZO and PPG. production process based on high-end production machines that are imported from Germany. It also features fully enclosed production areas and strict quality control. aspects of the production line are monitored 24/7 every day. The skilled quality inspection team is monitoring production in real-time. The finished product is tested with 100% accuracy..carry a variety of equipment, including board flattening equipment, defect detectors and ultraviolet resistance testing equipment. Warranty period of 15 years.

Rogosteel provide a wide anodized aluminum sheet products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. We offer custom-designed services. Colors from RAL well as custom-designed colors for customers are available. is a broad range uses and is suited corrugated board/glazed tiles/sandwich panel/home appliances/power distribution cabinets keels.Relevant instances include the towns located in Eastern Europe, large domestic airports, Samsung factories in South Korea, Hisense refrigerators in Africa, government engineering procurement as well as port construction projects within the Middle East.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy