This is one of the most advisable option among all as Aluminum panels are widely use to build houses, offices etc. They are lightweight, super strong and go up very easily. Anodized aluminum panels are now being commonly used for a reason, they come with several special features which have made them distinguished and useful. This text focuses on the reasons why anodized aluminum panels are one of the best options for your buildings, whether you work with residential properties or commercial projects.

Anodizing: An extra process that works to make it stronger. This is accomplished by placing a unique layer on top of the aluminum. This layer also treats the panels from rust protection, bad weather and water will not hurt them. This received treatment allows anodized aluminum panels to have greater durability than traditional aluminum panels. They are also a safe way to do that, and for many of us we have our entire family at home all day so this is perfect.

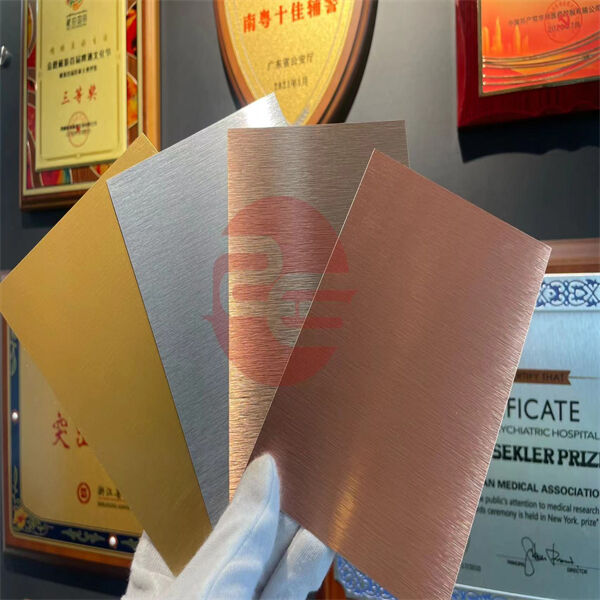

Anodized aluminum panels look nice and are available in a lot of colors. This indicates you can use them to beautify and color any construction of the land. That way, you can select a color based on your individual style or the vibe of that particular corner of your home. Moreover, it is more environmentally-friendly because you do not need to paint your walls later. This cuts back on time and reduces the amount of harmful chemicals needed (they come from paint!)

Anodized aluminum, panels are the strongest of them all. They are capable to deal with adverse weather such as heavy rain and strong wind, snow etc. These are specially designed for rapid hits and impacts, so they make the best pairing with busy locations like hallways or waiting rooms. Since they are resistant to scratches and dents, even high-traffic spaces will still appear good.

They are not only very resilient, however they also help reduce carbon footprints and maintain a look that is ecologically friendly. Anodization is created around a closed loop, using materials over and over to cut down on waste - including water as the process of anodizing uses such little volume. In other words, this makes production of those panels more planet-friendly and less harmful.

Highly versatile, anodized aluminum panels can be featured in a wide variety of design applications. This modern aesthetic is common in both commercial buildings and homes. This endless compatibility allows them to be used in a wide range of situations, whether it is office environments, at schools or even in hospitals.

The Latest JEI Discovery: The Untold Secret Of Anodized Aluminum Panels Is That They Can Be Cut Into Any Form Or Design This flexibility makes them the ideal solution for special projects where you might need to make custom panels that fit certain areas. Whether you are looking for a large panel that covers an entire wall or small piece of aluminum in order to have as unique build, the panels fabricated from aluminium can be customized accordingly so it meets your exact requirements.

Rogosteel has nine production lines with an annual output 2,000,000 tons and has made long-term strategic agreements with more than 20 expert logistics agents major domestic customs brokers for ports to ensure the effectiveness shipping cargo. We are able to work with our customers process various testing certificates and certification the document of customs clearance to ensure the delivery their goods. includes the BV certificate, CO Embassy certification, more.company has a professional after-sales anodized aluminum panelsthat monitors the after-sales process throughout the process. They are available 24 hours a day. Within 12 hours, the business will respond to any after-sales problems and offer solutions within 24 hours.

an anodized aluminum panelsfocused on exports, ROGOSTEEL has focused over past decade on improving product quality and promoting services. ROGOSTEEL has developed collaborative relationship with over 500 customers across Asia, Europe and South America. company also has earned a reputation for their pragmatic approach integrity.company has been awarded "Shanghai Best Export Enterprise" and China Inspection-Free Products" as well as "Alibaba Outstanding Trade" over a period of time. The client satisfaction rating is 100%.

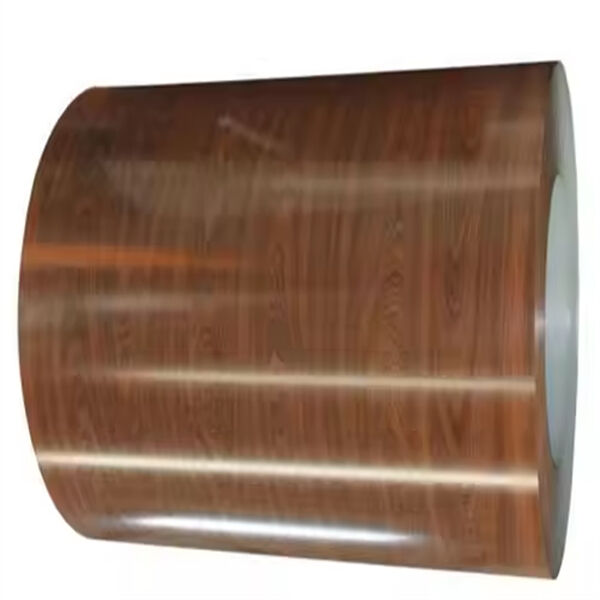

Rogosteel provide wide range of products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. Customized services are available in 1825 colors RAL as well as color options that can be customized by customers.product is perfect many different applications for anodized aluminum panelsboards, such glazed tiles/sandwich panel, home appliances, power supply cabinets, and keels.Examples of relevant cases include the construction ports in Middle East, government engineering procurement and large airports Eastern Europe.

Rogosteel has been certified by the ISO9001 Quality Management System, ISO14001 environmental management system OHSAS18001 occupational health management system, SGS/BV and other certifications. raw materials of the product substrates come from Tangshan Iron and Steel and HBIS, and the product paints come from internationally renowned brands like AKZO and PPG. The technology behind product utilizes high-end manufacturing equipment that is imported from Germany. facility also has an anodized aluminum panelsproduction workshop strict quality controls. Every aspect the production line are monitored 24/7 every day. expert quality inspection team oversees production real-time. The success rate of the final product testing is 100%.We stock a wide range of instruments, including board flattening equipment, defect detectors, as well as ultraviolet resistance testing equipment. Warranty of 15-years.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy