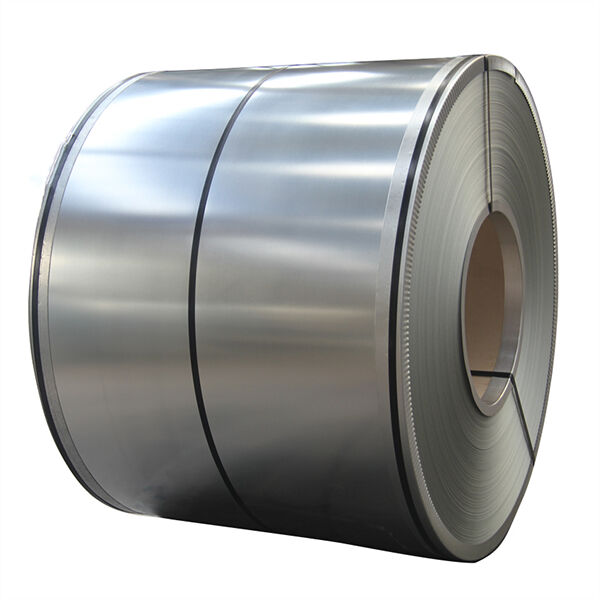

Kupitia Usinzia wa Chuma cha Kujaliwa na Elektroni Usinzia hizi ni aina ya upatikanaji wa kifaa ambacho inaweza kupongwa kwa chuma. Kupata kubeba kuhusu usinzia wa chuma cha kujaliwa na elektroni, tutajua kiasi cha kipengele kinachotokana na muhimu huu. Katika usinzia wa chuma cha kujaliwa na elektroni, chuma chinapongwa katika bathi ya zincu na basi toleo la nguvu linapongwa. Hii inawezesha zincu kuunganisha na chuma, kuanza kifaa cha kibofu cha daima.

Sababu za Usanidi wa Kigalvanize Elektroni Sababu kubwa ni kuwa usanidi wa ziho hupunguza chuma kutoka kuharibika na upepo au upunguzi. Hii ni hasa muhimu kwa bidha ambayo zitakapokuwa zinategemea maji au kimia makali. Pia, jukwaa la ndogo lililoipangwa na kigalvanize elektronik linatoa usimamu wa mchanganyiko ulioamriwa kwa kupanga rangi.

Mambo ya kuharibisha kwa juhudi zinatumika kwa kufanya na usimami wa kuangalia. Chuma ni mstari, lakini chuma inaweza kupepea ikiwa ni mbichi au kimepata hewa. Kwa sababu za miaka mingapi zaidi tunaweza kuongeza umri wa mambo ya chuma kwa kuharibisha kwa juhudi tunavyoweza kuongeza kifaa cha ziho ambacho inamasiria kifaa, hivyo kubadilisha milango ya muharibi.

Jinsi gani mataifa ya baradi viongozi vinapovikawa na vinginevyo vya usimami? Uumbaji mkubwa unaofanya tofauti ni jinsi ilivyotumika. Lakini katika kuharibisha kwa juhudi, ndoto inahusisha chuma na ziho; usimami mwingine, kama haribisho la kupiga moto, inahusisha kupakua chuma katika ziho la moto. Yoyote inatumiwa, wakati mwingine, haribisho ya juhudi inapendekezwa kwa nini? Viungo vya upana.

Chuma cha kujaliwa na elektroni huru unapatikana katika sehemu nyingi. Kwa mfano, katika ufanisi wa magari, usinzia wa chuma cha kujaliwa na elektroni hutumika kuhifadhi sehemu za magari kutoka kufura. Pia, visavani na mifumo ya jengo katika jiandamano inavyojengwa kwa kutumia chuma cha kujaliwa na elektroni. Chuma cha kujaliwa na elektroni pia inapatikana katika usanuzi, hasa katika mbao, mitisho ya kupasua ndoto, na mebla.

Hakiki © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD. Huu ina haki zote - Sera ya Faragha