သူရဲ့ရောင်ကို အသစ်တစ်ခုအဖြစ် အသုံးပြုလိုက်ပါတယ်။ ဒါဟာ အများအပြားသော အမြင်အရောင်းများနဲ့ အမြင်အရောင်းများကို ပေးပါတယ်။ ဒါဟာ အများအပြားသော အရောင်များနဲ့ အမြင်အရောင်းများကို ပေးပါတယ်။ ရောင်ပြင်များနဲ့ အမြင်အရောင်းများကို ပေးပါတယ်။ ဒီမှာ အခြားအချက်များကို ပေးပါတယ်။ ဒီမှာ အခြားအချက်များကို ပေးပါတယ်။ ဒီမှာ အခြားအချက်များကို ပေးပါတယ်။

ဒါက ကျွန်တော်တို့အိမ်ခြင်းနဲ့ အလှပုံဆောင်ရွက်မှုမှာ color coated aluminum coil ကို သုံးဖို့ လိုအပ်တဲ့ အကြောင်းပါ။ ပထမဆုံးက ဒါဟာ လျှော့ချထားတဲ့အခါ အလေးချိန်ကို လုပ်ငန်းစဉ်တွေနဲ့ ဆိုင်ရာပြောပြပါမယ်။ ဒါဟာ လျှော့ချထားတဲ့အခါ အလေးချိန်ကို လုပ်ငန်းစဉ်တွေနဲ့ ဆိုင်ရာပြောပြပါမယ်။ ဒါပေမယ့် အဆိုပါအရာကို အလွယ်တကူ ဖြစ်ပေါ်လာစေရန် အချိန်နဲ့ အကျိုးအမြတ်ကို သိမ်းပိုက်ပေးပါတယ်။ ဒါဟာ အမှန်ပါပဲ။ ဒါပေမယ့် အဆိုပါအရာကို အလွယ်တကူ ဖြစ်ပေါ်လာစေရန် အချိန်နဲ့ အကျိုးအမြတ်ကို သိမ်းပိုက်ပေးပါတယ်။ အဆိုပါအရာကို တည်ဆောက်ထားတဲ့အရာ သို့မဟုတ် အပိုင်းတစ်ခု၊ ဥပမာ renovation တွေမှာလည်း အသုံးဝင်ပါတယ်။

ဒုတိယအကြောင်း၊ ရေငံးဖျာထဲမှာရောင်ခြည်ထားသော aluminum coil ဟာ အလွန်ပြင်းထန်သည်။ ဒါဟာ ဆေးမီးကြီးနှင့် မီးကြီးများကို မက်ထိုင်းဘဲ ခံစားနိုင်သည်။ ဒါပေမယ့် မီးကြီးမှာ မက်ထိုင်းဘဲ ခံစားနိုင်ပြီး ရောင်ခြည်ကို မပျောက်ဘူး၊ မဝါရောင်လာဘူး သို့မဟုတ် မပျောက်ဆုံးဘူး။ ဒါကြောင့် ဒါဟာ အခြားသော ရာသီဥတုများနှင့် ပတ်ဝန်းကျင်များမှာ အသုံးပြုနိုင်ပါတယ်။

နောက်ဆုံးအကြောင်းမှာ ဒါဟာ အလွယ်တကူ မော်ကွေးပြီး အကောင်အထည်ဖော်မှုကို အကောင်အထည်ဖော်ပေးပါတယ်။ ဒါကို ရောင်ခြည်ပြောင်းရန် သို့မဟုတ် မျဉ်းချောင်းတွေကို မလိုအပ်ပါဘူး။ ဒီတော့ ဘေးဝိပ်များဖြင့် Cricut Mat ကို ရေမှားသောအခါ ဘာလို့သို့ မဆင်းရှင်းပါ။ ဒါဟာ ကျောင်းများ၊ ဆေးရုံများနှင့် အိမ်အခြားများ အတွက် အသုံးပြုနိုင်ပါတယ်။ ဒီနေရာတွေမှာ အားလုံးကို သန္တာရေးထိန်းသိမ်းရန် အရေးကြီးပြီး အချိန်တွေက မှီခိုပါတယ်။

အနောက်ဆုံးမဟုတ်သော်လည်း၊ ရေငှာခြောက်ဖြင့်ထိုးထားသော aluminum coil သည် တည်ဆောက်ရေးအပြင်အဆင်ပြေစွာလွယ်ကူသည်။ အင်္ဂါသည် ကျွန်ုပ်တို့၏ ကုန်ကျစရိတ်များကို သတ်မှတ်ရန် မလိုအပ်ပါ။ ဒါပေမယ့် အဆောက်အအုံမှ အပူချိန်နှင့် အလင်းကို ပြန်လွှားပေးပြီး အပူပြောင်းမှုနှင့် အပူချိန်ကို လျော့နည်းစေရန် ကူညီပေးသည်။ ဒီတော့ အင်္ဂါကျော်ကြားမှုကို ကျွန်ုပ်တို့၏ ကုန်ကျစရိတ်များကို သိမ်းဆည်းပေးပြီး ပိုင်းဝဲသော အင်အားကို လျော့နည်းစေရန် ကူညီပါသည်။

ရေငှာခြောက်ဖြင့်ထိုးထားသော aluminum coil ထုတ်လုပ်ရေးလုပ်ငန်းသည် ရှုံးလွှားမဟုတ်ပါ။ ပြီးခဲ့သော ရာစုတွင် အသုံးပြုခြင်းဖြင့် ယခုအခါတွင် များစွာသော အကျိုးသော အသုံးပြုချက်များကို အသိအမှတ်ပြုခဲ့ပါသည်။ အလျားခြောက်သည် ပထမဆုံးတွင် ကြောင်းများနှင့် အခြေအနေများကို ဖယ်ရှားရန် ရွှေ့ပြီး သိမ်းဆည်းရမည်ဖြစ်သည်။ ဒါပေမယ့် အလျားခြောက်သည် အလျားခြောက်သို့ ကျောက်ကြပ်မှုများ မပြုလုပ်ရန် အကြံပြုပါသည်။ ကြောင်းများနှင့် အခြေအနေများသည် အလျားခြောက်ကို ကျောက်ကြပ်စေရန် အကြံပြုပါသည်။

အပိုင်းတစ်ခုလား၊ သင့်ရဲ့ ကောင်းကို အချိန်တည်းတွင် စစ်ဆေးဖို့လိုအပ်ပါတယ်။ မြေဗျားတွေဟာ သင့်ကားထဲမှာ ဝင်လာတဲ့အခါ ဒီမှာ ဘယ်လို ပျက်ကွက်မှု သို့မဟုတ် အခြားအချက်များရှိနေမလား စစ်ဆေးဖို့လိုအပ်ပါတယ်။ ပျက်ကွက်မှုတစ်ခုရှိလျှင် ပျက်ကွက်မှုသို့မဟုတ် ကားရောင်းကို ဖြန့်ချိန်မှာ ကိုင်တွယ်ဖို့လိုအပ်ပါတယ်။ ဒီမှာ ပစ္စည်းကို အများဆုံးအသုံးပြုဖို့ ကူညီပေးတဲ့ အရောင်းအဝယ်များပါဝင်ပါတယ်။

အnEnterprise တစ်ခုအဖြစ် ROGOSTEEL သည် ပণ္နာရောင်ဆွဲထားသော aluminum coilover ကို မူလ ၁၀ နှစ်အတွင်း ပণုပ်ဒေသများ၏ အရှေ့အဆုံးအဆင့်ကို တိုးတက်စေရန် နှင့် ဝcrofting အရှိန်အဆင့်ကို တိုးတက်စေရန်အတွက် အလုပ်လုပ်ခဲ့သည်။ အလုပ်သမားများ၏အားလုံး၏အကြောင်းအရာများဖြင့် ROGOSTEEL သည် အာရှ၊ ဥရောပ၊ တောင်အမေရိက၊ အိုးရီးယားနှင့် အာဖရိကတို့၏ ၁၀၀ ကျော်နိုင်ငံများမှ ၅၀၀ ကျော်anggan များနှင့် ပူးပေါင်းဆောင်ရွက်ခဲ့ပြီး honesty နှင့် pragmatic approach တို့ဖြင့် ကောင်းမွန်သော အမြင်ရှိခဲ့သည်။ ၂၀၁၄ ခုနှစ်တွင် ကုမ္ပဏီသည် ISO9001 quality နှင့် management system certification၊ KS certification၊ SGS နှင့် BV test certificates တို့ကိုရရှိခဲ့ပြီး 'Shanghai's Most Export-oriented Enterprise'၊ 'China Inspection-Free Products' နှင့် 'Alibaba Excellent Trade Businessmen' တို့အဖြစ် တစ်ခုခုတွင် ခံစားခဲ့သည်။ anggan များ၏ satisfaction သည် ၁၀၀% ဖြစ်သည်။

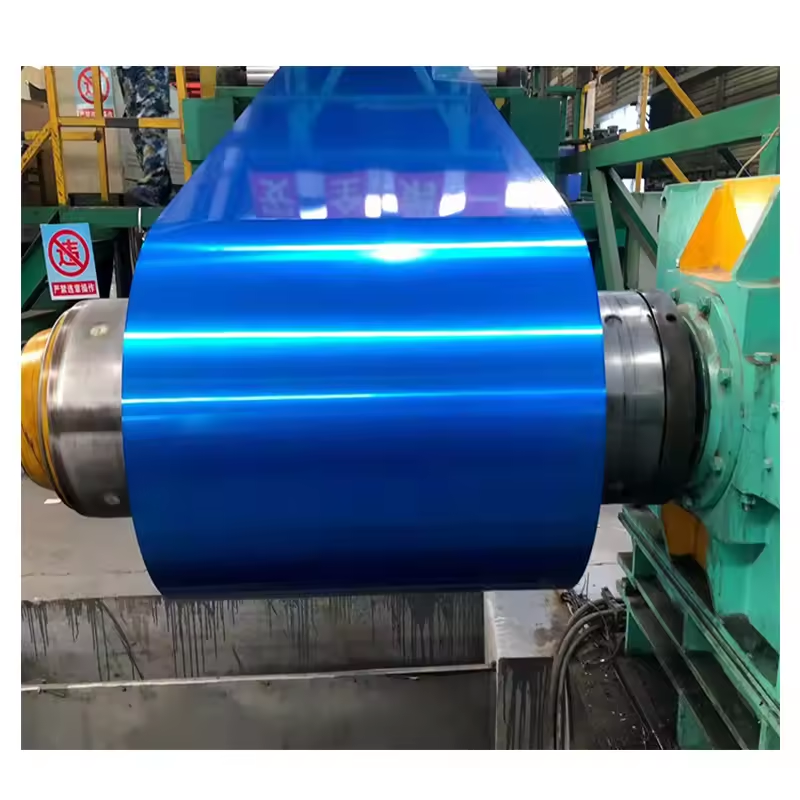

Rogosteel သည် အရဲကြီးပণုများကို ပေးဆောင်ပြီး၊ galvanized/galvanized/color-coated steel coil (matt ppgi/embossed ppgi/home appliance panel ပါဝင်သည်)၊ roofing sheets၊ cold rolled aluminum coil တို့ကို ပါဝင်သည်။ 1825 RAL ရောင်များနှင့် ခြောက်သူများ၏ ရောင်လွှမ်းများဖြင့် ပြုလုပ်ထားသော ပုံမှန်အားဖြင့် ဝယ်ယူသူများအတွက် ပုံမှန်အားဖြင့် ဝယ်ယူနိုင်သည်။ ထို့ပြင် color coated aluminum coilboards တွင် အသုံးပြုနိုင်သည့် အသုံးအဆင်များစွာရှိပြီး၊ glazed tiles/sandwich panel၊ အိမ်ထောင်စုများ၊ အားလုံးကို ပို့ဆောင်ရေးကို ပြုလုပ်နိုင်သည်။ ပတ်သက်သော ကြောင့်အားဖြင့် အလုပ်လုပ်သူများ၏ အကြောင်းအရာများကို ပြောင်းလဲနိုင်သည်။ ဥပမာ၊ Middle East တွင် ဆောက်လုပ်ရေးများ၊ အစိုးရ အစိုးရအားဖြင့် ဝယ်ယူသော အလုပ်များ၊ Eastern Europe တွင် ကြီးမားသော လေဆိပ်များပါဝင်သည်။

Rogosteel သည် SGS/BV မှ အတည်ပြုခံရသော ISO9001, ISO14001, OHSAS18001 နှင့် OHSAS18001 နှင့် ISO14001 ပณ္ဏုစီမံကိန်းစနစ်များဖြင့် အရောင်ထုတ်လုပ်ထားသော အလူမီနီယမ်ကိုင်။ အခြေခံပণုများအတွက် ရောင်းဝယ်ထားသော မူရင်းပစ္စည်းများသည် Tangshan Iron and Steel နှင့် HBIS မှ ဆင်းရဲသော ပစ္စည်းများဖြစ်သည်။ ထုတ်လုပ်ရေးလုပ်ငန်းတွင် အသုံးပြုသော ရောင်ဗျားများသည် AKZO နှင့် PPG အတွင်းပါသော ကမ္ဘာ့အဆင့်အတန်းမြင့်သော မာတိကာများမှ ဖြစ်သည်။ ထုတ်လုပ်ရေးပိုင်းတွင် အသုံးပြုသော ပညာရေးသည် ဂျာမနီမှ นำเข้าထားသော အမြင့်ဆုံးအဆင့်အတန်းရှိ ထုတ်လုပ်ရေးကိရိယာများကို အသုံးပြုသည်။ ထို့အပြင် ပုံမှန်ထုတ်လုပ်ရေးဆိုင်များကို ပြည့်စုံစွာ ပိတ်ပင်ထားသည်၊ ပြင်ပြင်ဆင်ဆင်ရေးကို ကြီးမားစွာ ထိန်းသိမ်းထားသည်။ ထုတ်လုပ်ရေးလုံးဝဲကို အခွင့်အရေးပြုသူများအဖွဲ့မှ ပုံမှန်စစ်ဆေးသူများက တကယ်တော်လို အကြောင်းကို စစ်ဆေးထားသည်။ ထုတ်လုပ်ထားသော ပণုသည် ၁၀၀% မှန်ကန်စွာ စစ်ဆေးထားသည်။ ကျွန်ုပ်တို့မှာ စက်မှုများရှိသည်- ဇင်းအဆံ့အတိုင်း လုပ်ငန်းတွင် စာမျက်နှာတွင် အမှားများ စစ်ဆေးရေးစက်မှု၊ ဘုတ်ပြုပြင်ရေးစက်မှုနှင့် UV ကာကွယ်စက်မှု။ အမှန်တကယ် ၁၅ နှစ်အကြာ အမှီအခိုပေးသည်။

Rogosteel သည် 9 ခုမြောက်ထုတ်လုပ်ရေးလိုင်းများ၊ နှစ်စဉ်ထုတ်လုပ်ရေးအထွက် 2,000,000 တန်ရှိပြီး ၂၀ ကျော်ဖြင့် ပိုင်ဆိုင်ရာ လိုဂျစ္စစ်များနှင့် အရှေ့ရောင်းအရှေ့ဝယ် စာချုပ်များကို ထိုင်ခဲ့ပြီး အများဆုံးအခြေပြု ဒေသဆိုင်ရာ ကျူးလွန်မှု ဌာနများနှင့် ပြောင်းလဲမှုများကို အကြံပြုပါသည်။ သင်္ကေတများ၊ စက်မှုများကို စာရင်းသွင်းရန် အကြံပြုပါသည်။ ထို့ပြင် BV သင်္ကေတ၊ CO အမှုဆောင်ရာသင်္ကေတများပါဝင်သည်။ ကုမ္ပဏီတွင် အမြဲတမ်း ၂၄ နာရီအတွင်း အမြန်အမှန်ဆိုင်ရာ ဝန်ဆောင်မှုအတွက် အသိမ်းထားသော ဝန်ဆောင်မှုအဖွဲ့ရှိပြီး ၁၂ နာရီအတွင်း အမြန်အမှန်ပြဿနာများကို ဖြေရှင်းပေးပါသည်။

ROGO INDUSTRIAL (SHANGHAI) CO.,LTD ၏ အားလုံးအခွင့်အရေးကို ကာကွယ်ထားသည် © - လျှို့ဝှက်ဖွယ်ရာမူဝါဒ