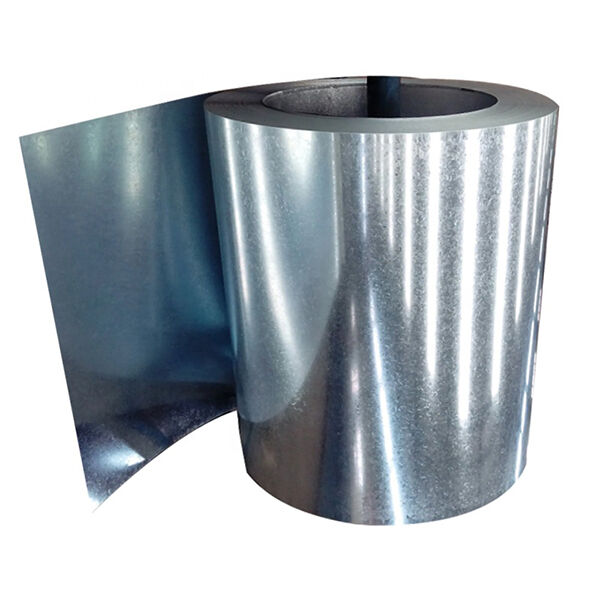

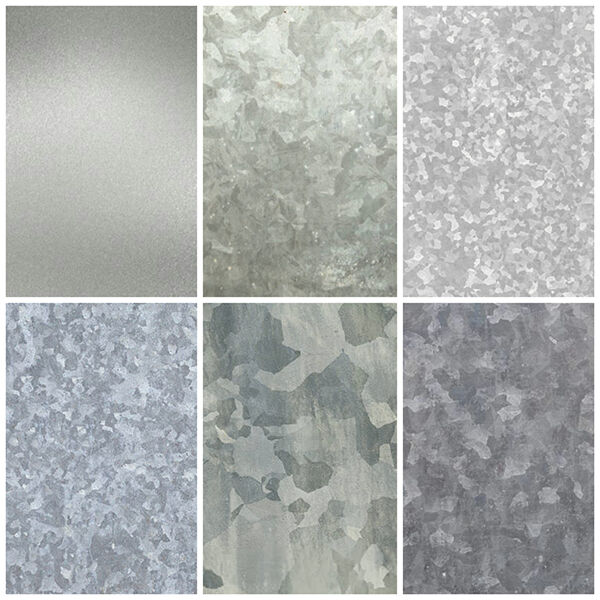

HDG Coil HDG, or hot-dipped galvanised (zinc coated) steel, is a process where the steel is dipped into a molten bath of zinc, This means the zinc-coated steel offers resistance to corrosion. This zinc is what helps to shield the metal from rust and corrosion. Workers dip the hot dipped galvanized steel coils into hot, liquid zinc to create HDG coils. This forms a durable protective barrier on the metal. HDG coils are employed by numerous industries, from construction to car manufacturing.

There are a lot of great reasons why ROGO prime hot dipped galvanized steel coils are used in so many industries. One major reason is that they are extremely resistant to corrosion. This is one reason why metal parts, in the aggregate, last longer. HDG coils are also durable and wear resistant, excellent for harsh environments. And at the same time, the zinc coating makes them look neat and smooth, providing a better looking finished product.

Proper handling and storage are essential to keep HDG coils in good condition. The right equipment and approach should be used to transport galvanized sheet metal coils to prevent them from becoming damaged or for workers to get injured. HDG coils need to be placed in a dry place with sufficient ventilation to prevent the collection of moisture, which may result in rust. It’s also crucial to stack the coils carefully to avoid bending or warping the metal sheets.

HDG coils are very helpful and useful, but we should consider for our environment. Producing HDG coils requires a great deal of energy and resources, and may lead to environmental pollution. But ROGO HDG coils last a long time and have a long replacement cycle. This limitation has waste-reducing benefits and is also efficient in terms of resources.

There are a number of things to consider when selecting your HDG coils for your project. First off, know what you need for your project — for instance, the thickness and size of the metal sheets. Also how much corrosion resistance do you want and are you concerned about looks? So, select a good manufacturer, like ROGO, who can provide you good quality galvanized sheet metal coils and good service.

Rogosteel has 9 production lines, with annual output of 2,000,000 tons has made long-term strategic agreements with more than twenty professional logisticians and largest domestic port customs brokers to guarantee the effectiveness of cargo shipping. are able assist customers to Hdg coilsvarious certificates testing certificates for customs clearance form goods delivery. This includes the BV certification, CO Embassy certification, etc.The company has a qualified after-sales department that monitors the after-sales service throughout the process and is online 24 hours a day. Within 12 hours, the company will respond to any after-sales issues and provide initial solutions in 24 hours.

company was founded in 2013 ROGO INDUSTRIAL (SHANGHAI) CO., LTD. located in China's central economic zone Shanghai, which is an enterprise that focused on exports within J.X.Y Group.As an export-oriented company in the last 10 years, Hdg coilsfocused on improving the quality of their products as well as expanding the services offered. ROGOSTEEL has built a cooperative partnership with more than 500 customers from Asia, Europe and South America. also have reputation for their pragmatic approach honesty.company was awarded the "Shanghai Best Export Enterprise", China Inspection-Free Products", and "Alibaba Outstanding Trade" over a period of time. The client satisfaction rating is 100%.

Rogosteel certified by SGS/BV, ISO9001, ISO14001, OHSAS18001, OHSAS18001 and ISO14001 quality management systems. Raw materials for product substrates are sourced from Tangshan Iron and Steel and HBIS. paints for product are made by internationally renowned brands such as AKZO and PPG. product's technology is based on high-end production lines that are imported from Germany with fully enclosed production workshops, as well as rigorous quality control. All Hdg coilsof the production line are monitored 24 hrs throughout the day. A skilled quality inspection team is monitoring production in real time. pass rate of finished product testing is 100 100%.We offer instruments like zinc layer dynamic monitoring equipment, defect detection boards flattening equipment and ultraviolet resistance testing equipment. Warranty 15 years.

Rogosteel provide a wide Hdg coils products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. We offer custom-designed services. Colors from RAL well as custom-designed colors for customers are available. is a broad range uses and is suited corrugated board/glazed tiles/sandwich panel/home appliances/power distribution cabinets keels.Relevant instances include the towns located in Eastern Europe, large domestic airports, Samsung factories in South Korea, Hisense refrigerators in Africa, government engineering procurement as well as port construction projects within the Middle East.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy