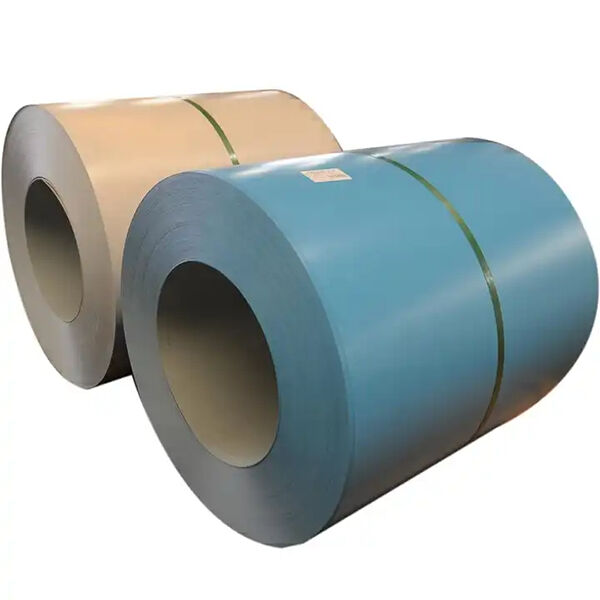

PPGL coil specification is a critical factor to consider in all sandwich panel projects. This is why it is critical to understand sandwich panels and the importance of PPGL coil specifications in order to ensure success of your project. PPGL is another common term for a coated steel coil it stands for pre painted galvanised layer and its the primary steel that goes on the outside of any sandwich panel to be both visually appealing to give a physical barrier protection

Choosing the Right PPGL Coil

Some factors to consider Choose the Right Thickness The coating type The colors The Durability of Coating The thickness of the coil will depend strength and weight properties for sandwich panel, while type of coating affects corrosion resistance property as well as weathering property. Regarding the specific choice of color, it will directly impact your project's look and decide between longer or shorter lasting sandwich panels

This informs you about how different PPGL coil options are better choice for the application of sandwich panel

While some PPGL coils will be cheaper and less durable, others would cost more but deliver a higher lifetime performance. The Pros and Cons of All Amendments Need be Considered First

Consulting with an industry expert, researching a variety of PPGL coil specs, and requesting samples to test the coating quality are some strategies for judging whether or not you will achieve your project goals

The answer to this and other questions will come when you take the time to assess the details of the PPGL coil, sparing your project from a number of possible conflict areas that might bring about problems and disappointment

When it comes to choosing the right PPGL coil for your sandwich panel, expert advice is always to work with a reliable supplier such as ROGO

The different varieties of ROGO PPGL coil for sandwich panel with varying thickness, coating standard, color and durability are provided. Contact us to get expert help finding the right PPGL coil for your project

To put it briefly, your sandwich panel project is only be complemented if you will use the right specification of PPGL coil so as to have a great finish that last longer and works according to requirements. But with these ways to distinguish PPGL coil specifications, examining crucial factors, comparing options and looking the best advice can help ensure the success in your project. Opt for ROGO as a producer of premium PPGL coils which are just the right fit for your requirement and offers more on table that what you expect

Table of Contents

- Choosing the Right PPGL Coil

- This informs you about how different PPGL coil options are better choice for the application of sandwich panel

- Consulting with an industry expert, researching a variety of PPGL coil specs, and requesting samples to test the coating quality are some strategies for judging whether or not you will achieve your project goals

- When it comes to choosing the right PPGL coil for your sandwich panel, expert advice is always to work with a reliable supplier such as ROGO