We hope this blog will help you to understand the price difference of PPGI and PPGL coils

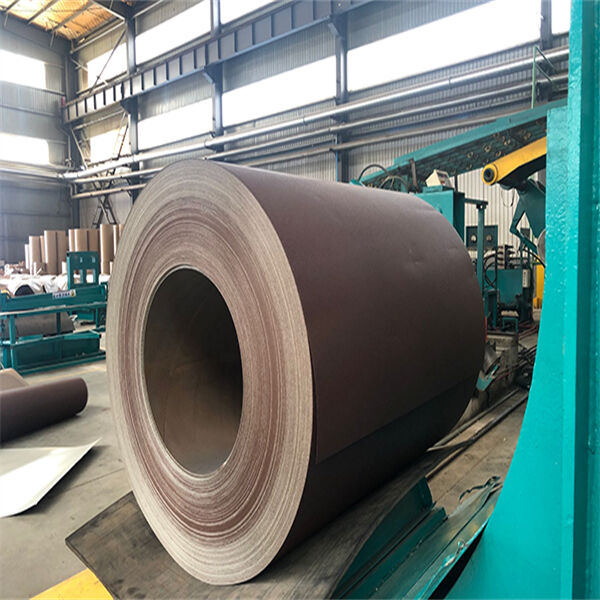

One of the most critical points to be noted while selecting PPGI and PPGL coils is their cost variation. Pre-painted steel) are high quality steel contract production, PPGI is (Separated by a layer of chemical composition; PPGL is (Galvaneal). These coils are utilized in diverse industries to create a plethora of products like roofing sheets, appliances and automotive parts

Factors affecting cost differences in PPGI and PPGL coils Explained

The price difference of PPGI and PPGL coils is determined by many aspects. What are the differences between Ceramic coils and Others? PPGI coils are formed with the use of galvanized iron, and PPGL coils are made out of galvalume iron. Since galvalume iron consists of a mix of galvanized steel and aluminum, it is more expensive than galvanized iron

Economic Comparison of PPGI & PPGL coils

While PPGL coils are a bit more expensive than PPGI coils, the former also hold economic benefits. The addition of aluminum in the coating makes the PPGL coils more robust and resistant to corrosion. This gives the products made using PPGL coils a longer life and hence lesser maintenance, which helps save money in the long run

Understanding the Economic Impact of Selecting PPGI and PPGL coils

PPGI coils are lower in cost and more reasonable than aluminum, at least in a short time period. However, if one were to think about the long-term costs of buying and owning PPGL coils are more cost-effective. As a result of the competitiveness and high quality of products produced from PPGL coils, maintenance expenses are reduced along with significantly impressive service life of these products which otherwise saves money to one in the long run

Understanding cost differences in PPGI AND PPGL COIL MANUFACTURING PROCESSES

The manufacturing process also leads to differences in the costs and prices of PPGI vs. PPGL coils. Production of PPGL coils asks for an extra stage in which the coating could become aluminum-accumulated, thereby it brings up to production cost. This extra process makes PPGL coils costlier as compared to PPGI. The initial cost is greater, but the long term durability and corrosion resistance improvements of using PPGL coils far surpass using something cheaper

Ultimately though, what you may save on the upfront cost of PPGI coils will most likely be negated by the fact that PPGL is, in general, a far better value due to their longevity and strength. Economic advantages and financial implications of both types of coils: When considering the cost differences between PPGI and PPGL coils. To put it simply, which coil type to go for in your project will be influenced by the budget you have at hand, the longevity of the product as well as how often said product owner will continue to use their installation. With this challenge in mind, you will be able to make a pragmatic decision that revolves around minimizing your cost deliver benefits for your company that lie ahead. Remember, pick ROGO for all your coils

Table of Contents

- We hope this blog will help you to understand the price difference of PPGI and PPGL coils

- Factors affecting cost differences in PPGI and PPGL coils Explained

- Economic Comparison of PPGI & PPGL coils

- Understanding the Economic Impact of Selecting PPGI and PPGL coils

- Understanding cost differences in PPGI AND PPGL COIL MANUFACTURING PROCESSES