يجب أن تتساءل كيف لا تصدأ منتجات صاج الدونفال؟ إنه موضوع مثير للاهتمام، وأنا متحمس لأشرح لك ذلك. صاج الدونفال هو نوع خاص من الصلب يتم طلاء سطحه بطبقة من الزنك. تعمل هذه الطبقة كحاجز لا يُخترق ضد المياه والهواء التي قد تؤدي إلى تآكل الصلب. ويحدث الصدأ في الصلب بشكل رئيسي بسبب تفاعل المياه والهواء مع سطحه. وبالتالي، وبكل اختصار، يساعد صاج الدونفال على إعادة استخدام الزنك (بسبب الطلية) ويمنع الصلب من التعرض للخدوش والتلف، مما يحافظ عليه لفترة أطول.

نصائح لزيادة عمر صاج الدونفال

الآن بعد أن فهمت كيف يمنع الفولاذ المجلفن (GI) تآكل الصدأ في أنبوبك، اسمح لي بشرح بعض الأمور المتعلقة بكيفية جعل منتجاتك تدوم لسنوات وسنوات. إصدارات مطلي بالزنك فولاذ وبالتالي، فإن النقطة الأساسية التي يجب أخذها هنا هي الحفاظ على نظافة وتجفيف منتجاتك المصنوعة من الفولاذ المجلفن (GI). إذا كان هناك ثقب صغير أو شق في طبقة الزنك، يمكن للماء أن يتسرب ويؤدي إلى تكون الصدأ. لذلك من الجيد جدًا تنظيفها بانتظام والتحقق منها للتأكد من حالتها الجيدة. يمكن مسحها بقطعة قماش بسيطة وقليل من الصابون المعتدل. وللحصول على حماية إضافية ضد الصدأ، يمكنك أيضًا تطبيق طبقة إضافية من الطلاء الوقائي، مثل الدهن أو مادة ختم مُحضرة خصيصًا، على منتجاتك المصنوعة من الفولاذ المجلفن (GI). هذا يضيف طبقة إضافية بمثابة درع إضافي لمساعدتك في حماية ممتلكاتك.

أين ترى الفولاذ المجلفن (GI) في العالم الحقيقي

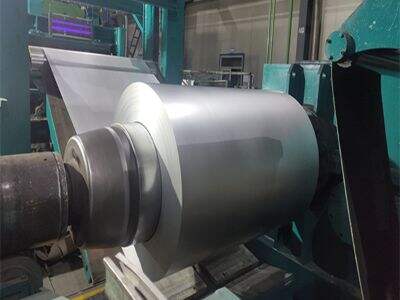

يُستخدم الصلب المجلفن (GI) على نطاق واسع، وقد يفاجئك قراءة مدى انتشار مصادفتنا له في حياتنا اليومية. يمكن العثور على الصلب المجلفن في الأجهزة الكهربائية المنزلية مثل الثلاجة أو الموقد، وكذلك في مواد بناء المنازل. على سبيل المثال، gi steel coil التي تُستخدم لبناء سقف منزلك ستقوم بحمايته من جميع الظروف الجوية مثل المطر والثلج وغيرها. كما يُستخدم هذا النوع من المعادن في السيارات والحافلات والشاحنات. ويُستخدم الصلب المجلفن بشكل كبير في المركبات لأنه يجعلها متينة وقوية. في المرة القادمة التي تلقي نظرة حولك، حاول التعرف على ما إذا كان هناك صلب مجلفن من حولك - فقد تفاجأ بأنك تجد أكثر مما تتوقع.

اختيار طلاء عالي الجودة يوفر المتانة

يعد اختيار الطلاء المناسب أمرًا بالغ الأهمية لضمان حماية منتجاتك من الصلب المجلفن ضد الصدأ. توجد في السوق أنواع مختلفة من الطلايات، ولكل نوع ميزاته وعيوبه. هناك عدة أنواع من الطلايات مثل طلاء الدهان، والطلاء البودري، والطلاء الإيبوكسي، وغيرها. وسيعتمد الاختيار الأمثل للطلاء على توافق المنتج النهائي مع الطبقة الزنكية الموجودة أسفله وعلى مستوى الحماية المطلوب أيضًا. صفيحة gi بالإضافة إلى ذلك، فإن درجة الحماية المطلوبة. إذا كنت لا تعرف أي طلاء يجب اختياره، فقد يساعدك استشارة متخصص أو إجراء بحث بسيط في اتخاذ القرار الأنسب لاحتياجاتك. هذا سيساعد في الحفاظ على حالة منتجات الصلب المجلفن الخاصة بك بحالة ممتازة لسنوات عديدة.

الحفاظ على أمان الصلب المجلفن في البيئات القاسية

ليس من السهل الحفاظ على قطع الفولاذ المجلفن في الأماكن الصعبة، مثل تلك التي تتسم بارتفاع الرطوبة أو محتوى الملح في الجو. ولكن لا تقلق. فباستخدام الأدوات المناسبة والمعرفة الكافية، يمكنك بالتأكيد القيام بذلك. يشير الخبراء إلى أنه يجب عليك فحص العناصر الخاصة بك بشكل دوري للبحث عن علامات الصدأ أو التلف. إذا اكتشفت أي مشكلة، فمن الضروري للغاية معالجتها بشكل فوري قبل أن تتفاقم. بالإضافة إلى ذلك، تنظيف الفولاذ والتأكد من خلوه من الأوساخ والمخلفات يعد أيضًا وسيلة فعالة لمنع نمو الصدأ. يمكنك تحقيق ذلك باستخدام فرشاة ناعمة أو قطعة قماش لضمان نظافة السطح. إذن، مع العناية والصيانة المناسبة، يمكن لمنتجات الفولاذ المجلفن أن تدوم لسنوات قادمة، قوية وثابتة.