People use SPCC and SGCC to make things in the fields of construction, metal working, automobile manufacturing and other places. It’s good to know how they differ so you can decide which one to use for your work. So today we are going to discuss of two of the most common steel types we manufacture and sell in our Featured Steel Products Guide, spcc sgcc, and various factors that makes these two unique, and what people can use them for. Keep reading this blog to learn what it’s used for: it’s rust resistance, and how to be mindful when purchasing a steel product to get the right material based on intended usage.

SPCC refers to COLD rolled steel, and various others with like results SGCC is hot rolled, and others are not. “The primary difference between these two is the coating that the steel binder has on top of it. SPCC is base material of no surface treatment, and the image presented is slightly better than SPCC. SPCC is a little hard in mechanical properties than SPCC+CR, and also more worse in anti-oxidant experience. This coating of zinc inhibits rust. For this reason, SGCC is a better pointer than SPCC to fight against rust.

Between these two types, SPCC is the quality grade of the cold rolled steel and SGCC is the quality grade of the galvanized steel. If you are looking for an affordable product, you can go with the SGCC. But if you don’t need that robust level of rust protection, SPCC PRODUCT could end up being cheaper for you.

SPCC is also perfect as it is possible to shape or weld, so it is good for many types of work. It’s easy to handle, which is why a lot of manufacturers like to use it. SGCC, on the other hand, is praised for its strong resistance to rust, making it an ideal choice for outdoor jobs or use in places that could become damp.

SPCC is more prone to rust than SGCC because it does not have a protective coating. This implies that SPCC can not work in places where the mordant will prevent the surface from rusting. SGCC, on the other hand, is excellent at preventing rust, especially when it is exposed to moisture or in outdoor environments.

When you compare it with the material, both have something different to offer, but what it ultimately boils down to your project and what you can afford. If prevention of rust is needed, SGCC should be used. If you would like something easier in handling and less costly, maybe you can consider Steel Coil SPCC. Three: It is smart to consult a professional or a supplier like ROGO so they can help you choose the right material.

Rogosteel certified to the ISO9001 quality management system, ISO14001 environmental management system, OHSAS18001 occupational healthcare management system, SGS/BV other certifications. Raw materials for substrates for products are sourced from Tangshan Iron and Steel and HBIS. paints used in the production process manufactured by internationally recognized brands like AKZO and PPG. The technology used in the product is high-end production lines that are imported from Germany Fully enclosed production workshops, as well as rigorous quality control. production line is overseen by experts in the Spcc sgcc quality inspectors, in real-time. rate of passing testing of the product is 100 100%.stock a wide range of instruments, including: board flattening machines, defects detectors, as well as ultraviolet resistance testing equipment. Warranty of 15 years.

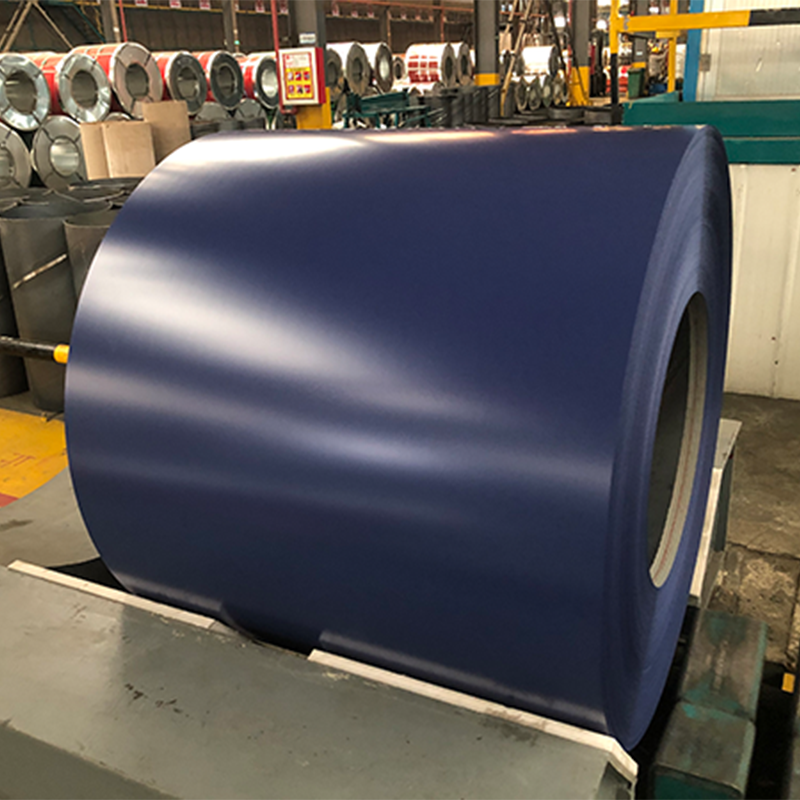

Rogosteel provide wide range of products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. Offer customized services: 1825 RAL colors customer-customized colors offered.It can be used a variety of applications. It ideal for corrugated board/glazed tiles/Spcc sgccpanel/home appliances/power distribution cabinets keels.Examples relevant cases include the building of port facilities in the Middle East, government engineering procurement, and major airports located in Eastern Europe.

Rogosteel has nine production lines, with annual output of 2,000,000 tons. has also developed long-term strategic partnerships more than twenty professional logistic agents as well as major national port customs brokers guarantee the effectiveness of cargo shipping. According to Spcc sgccpolicies can collaborate with the processing of various tests certification certificates in customs clearance documents goods delivery, including BV certification, CO embassy certification, etc. team of experienced after-sales specialists is on hand all hours of day to ensure service is being monitored. Within 12 hours, the business will be able to respond to any post-sales issues provide preliminary solutions within 24 hours.

an enterprise that is geared towards exports, ROGOSTEEL has focused over last decade on improving the product quality promoting customer service. By all staff's effort, ROGOSTEEL have built cooperative relations with over 500 customers from 100 countries in Asia, Europe, South America, Oceania Africa and gained solid reputation for their honesty and pragmatic approach.In 2014, business was able to pass ISO9001 quality Spcc sgccsystem certification with KS certification. Additionally, it has SGS and BV certifications testing and was given honor of being named "Shanghai's Best Export Enterprise", "China Inspection-Free Products" and "Alibaba Excellent Trade" for several consecutive years Businessmen". The satisfaction of customers is 100%.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy