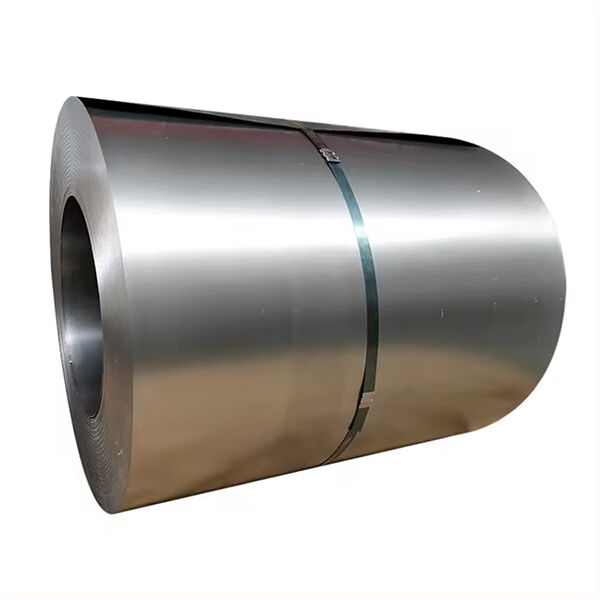

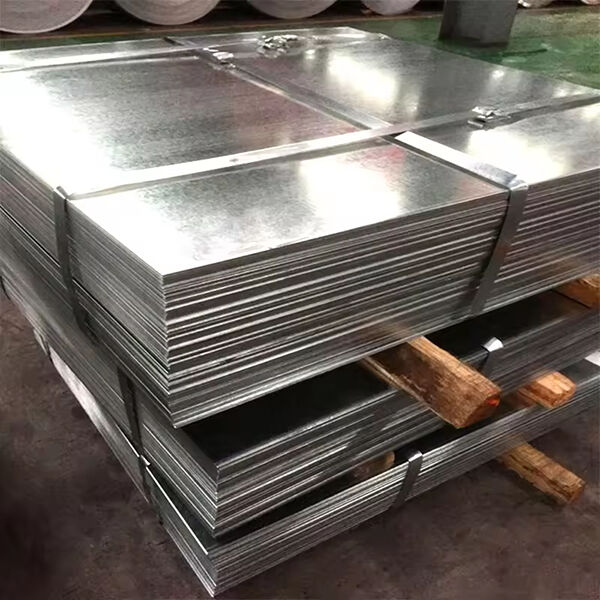

GI hot dipped galvanized coatings is a special layer that serves as protection for the metal to prevent rust. This ROGO is done with molten zinc and a process of dipping metal in hot zinc. It makes an impressive shell that protects the metal from anything that may cause damage. So, let’s take a closer look at GI hot dipped galvanized coatings, and why they do so well guarding metal against rust. GI hot dipped galvanized coatings have one major feature where they prevent rust and corrosion. It keeps gi sheet metal surfaces for a long time and requires lesser maintenance. In addition, GI coatings are eco-friendly and recyclable, a sustainable choice for metal protection.

GI hot dipped galvanized coating, process and steps. Clean the metal first to provide the best adhesion for the zinc. The ROGO metal is then immersed in molten zinc and coated with a protective layer. Then, the metal gi sheet metal is cooled before inspecting it to ensure the coating process has been properly performed.

GI hot dipped galvanized coatings are an excellent option for rust protection, as they form a robust barrier against destructive factors. It will also help metal surfaces last longer and require less maintenance, saving you time and money. ROGO GI coatings are also simple to apply and helpful on a wide variety of metal types, which gi steel sheet price makes them a solid solution for rust prevention.

Galvanized Iron (GI) hot dipped galvanized products are strong and beneficial in the sense that they can survive long against rust. The surfaces for metal will look as good as new for several years, in care conditions. And as gi sheet coil an added benefit, ROGO GI coatings do not scratch or chip easily, keeping the protective layer intact.

Metal needs to be regularly inspected and cleaned to sustain good condition. This rogo gi will help dislodge dirt or debris that may scratch the coating. A protective topcoat can also improve the overall strength of the GI coating and help keep the coating performing for longer.

an export oriented enterprise, ROGOSTEEL has focused over past decade on enhancing quality its products and improving service. ROGOSTEEL has built a cooperative relationship with more than 500 customers across Asia, Europe and South America. ROGOSTEEL also enjoys an enviable reputation for their practical Gi hot dipped galvanizedand integrity.The company was awarded the "Shanghai Best Export Enterprise" and China Inspection-Free Products", and "Alibaba Outstanding Trade" over a period time. Customer's satisfaction reaches 100%.

Rogosteel provide wide range products, including Gi hot dipped galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. Provide customized services: 1825 RAL colors custom-designed colors are available.It can be used a variety of applications can be used for corrugated boards/glazed tiles/sandwich panels/home appliances/power distribution cabinets/keels.Relevant examples the construction ports in the Middle East, government engineering procurement and large airports Eastern Europe.

Rogosteel has nine production lines with an annual output 2,000,000 tons and has made long-term strategic agreements with more than 20 expert logistics agents major domestic customs brokers for ports to ensure the effectiveness shipping cargo. We are able to work with our customers process various testing certificates and certification the document of customs clearance to ensure the delivery their goods. includes the BV certificate, CO Embassy certification, more.company has a professional after-sales Gi hot dipped galvanizedthat monitors the after-sales process throughout the process. They are available 24 hours a day. Within 12 hours, the business will respond to any after-sales problems and offer solutions within 24 hours.

Rogosteel certified by SGS/BV. ISO9001, ISO14001, OHSAS18001, OHSAS18001 and ISO14001 quality management systems quality Gi hot dipped galvanized. Raw materials for substrates products originate from Tangshan Iron and Steel and HBIS. paints used in the production process are made by internationally-renowned brands such as AKZO and PPG. technology behind the product utilizes high-end production machines that are imported from Germany. also features fully enclosed production workshops strict quality control. The production line is monitored by a professionals from the team quality inspectors, in real-time. The product that is produced is tested with 100% accuracy..We have equipment: zinc layer dynamic monitoring equipment, defect detection Board flattening equipment and UV resistance testing equipment. Warranty period of 15 years.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy