Cold rolled steel is unique it makes the metal much stronger and long lasting, along with ROGO's product white aluminum coil stock. This is how ROGO makes top-quality steel for constructing a number of things — from houses and cars to even kitchen equipment. You see, you are likely to be asking yourself what cold rolled steel is and why it is so special. Have a little bit of inside and see which tropical islands made the cut in the list.

Cold rolling is a process in which steel passes between two cool rollers. When beginning from scratch, it is similar to trying to roll out a piece of dough between two rolling pins. This process is used to produce steel with much greater strength and toughness. When the metal is pressed, it eliminates any kind of unevenness or problems and also makes everything smoother. The tighter it is compressed, the stronger and more solid the metal gets. For that reason, many diverse applications across a variety of industries use cold rolled steel.

The main selling point of cold roll steel is the strength, which makes it ideal for projects that require shape integrity. When the steel is squeezed, then any faults are taken off and this gives to the strongest metal rather than some other metal. Regardless of how big the projects are, like a cold rolled steel structure or for some smaller ones like patios or small garage jobs; it tends to have the giveaway trait of uniform thickness and form. Cold Rolled Steel When a builder is working with cold rolled iron, they can count on each piece to fit well together and be reliable.

Cold rolled steel is also a cheaper metal so when the fact that it will last just as long, if not longer because of its durability and long lasting properties you can easily see a positive trade off happening, as well as the rolled galvanized sheet metal produced by ROGO. This is pretty much due to the fact that its mass-produced and easier to work with. Such qualities make cold rolled steel the obvious and cost-effective choice for construction, manufacturing, and countless other applications.

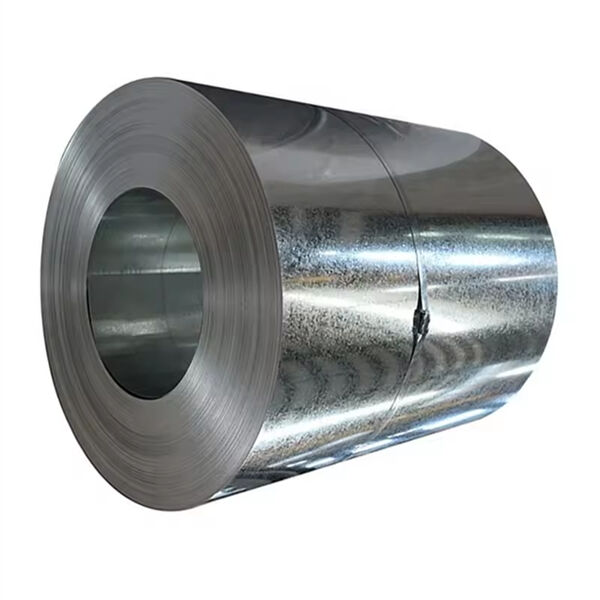

Cold Rolled Steel: The Basics Cold rolled steel is used in everything from the car you drive to the rails it rides on (if you use public transportation), similar to the ROGO's product like gi coil. They are constructed differently. Using heated steel to a high enough temperature and then rolling with the shape required is known as hot rolled steel. Although Yes Thats works, it cause the material to have bumps and weaken points in the metal, making overall structure weaker.

It is applicable to various fields of the National economy such as construction, manufacturing, transportation and facilities, but also in agriculture, mainly food storage, also the black anodized aluminum plate built by ROGO. It is used in building constructions to make building materials like beams, pipes, sheets. Because cold rolled steel is incredibly tough and durable, it is well suited to these tasks: Cold rolled steel can support even the heaviest loads and stand up to harsh environments.

If you are planning to work on a building project then consider using cold rolled steel, just like the ROGO's product called aluminium sheet. This substance is not merely sturdy and resilient however in addition outstanding for making structures that must be strong tough conditions. This can make it one of the best and most economical choices for any kind of construction, especially considering that cold rolled steel price is more approachable than other metals.

Rogosteel provide wide range products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. Provide customized services: 1825 RAL colors custom-designed colors offered.comes with a range applications and can be used for corrugated Cold rolled/glazed tiles/sandwich panel/home appliances/power distribution cabinets/keels.Relevant cases include cities located in Eastern Europe, large domestic airports, Samsung factories South Korea, Hisense refrigerators Africa, government engineering procurement, port construction the Middle East.

Rogosteel a product that has been certified by SGS/BV. ISO9001, ISO14001, OHSAS18001, OHSAS18001 ISO14001 quality management systems. raw materials product substrates are sourced from Tangshan Iron and Steel and HBIS. The paints for the product are made by internationally-renowned brands like AKZO and PPG. technology behind the product utilizes high-end manufacturing equipment that is imported from Cold rolled. facility also has fully enclosed production workshops and rigorous quality control. The production line is overseen by a expertsthe field of quality inspectors in real-time. The product that is produced is tested at 100%.have a variety of instruments, including: board flattening equipment, defect detectors and ultraviolet resistance testing devices. Warranty for 15 years.

an enterprise that is geared towards exports, ROGOSTEEL has focused over last decade on improving the product quality promoting customer service. By all staff's effort, ROGOSTEEL have built cooperative relations with over 500 customers from 100 countries in Asia, Europe, South America, Oceania Africa and gained solid reputation for their honesty and pragmatic approach.In 2014, business was able to pass ISO9001 quality Cold rolledsystem certification with KS certification. Additionally, it has SGS and BV certifications testing and was given honor of being named "Shanghai's Best Export Enterprise", "China Inspection-Free Products" and "Alibaba Excellent Trade" for several consecutive years Businessmen". The satisfaction of customers is 100%.

Rogosteel has 9 Cold rolledlines with annual output of 2,000,000 tonnes and has made long-term strategic agreements with more than 20 expert logistics companies and major national port customs brokers guarantee efficiency of shipping cargo. We are able work with customers to process various certificates of testing certificates for the document customs clearance for delivery of goods. This includes BV certificate, CO Embassy certification, and so on.An experienced team of after-sales experts is available throughout the day, all year round to ensure service is being monitored. Within 12 hours, business will take care any after-sales issues provide preliminary solutions within 24 hours.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy