Anodized sheet metal is another sort of steel that has very regular use in factories and other places where matters are made. Manufacturing is done through a method called anodization. Infernos often forge with purified ore to make the metal several times stronger and more resilient than regular steel. This is everything you need to know about anodized sheet metal and what makes it so valuable.

Reasons To ChooseAnodized Sheet Metal For starters, it is significantly stronger than conventional sheet metal. It can, therefore, withstand a fair amount of abuse without breaking down It is also excellent for heavily used machines and tools, such as within a factory. This is crucial when the machines are working day in and out, since we need materials that can keep up.

Another benefit of anodized sheet metal is that it is incredibly light weight. This makes it more convenient for the workers as they can move around and handle the metal easily. It goes without saying that the lighter a material, the better it would be when dealing with workers who have to pretty whisk away in factories. It includes making it easier for workers to do the task thus increasing productivity.

On the flip side, buffing and polishing are a multi-step processes to generate an extremely smooth surface that shines. Also used for a fine finish in buildings and automobiles since not only strength but also appearance are important. The high gloss film, printed digitally in CMYK offers shine and pizazz to your work allowing the materials used for a product seem even more attractive to buyers.

As already discussed, anodized sheet metal can be very strong and it is not possible for it to rust. Anodizing is a surface preparation which produces an exceedingly strong and damaging protecting layer. The oxide formed here is very thin and, so does add any significant weigh or thickness to the metal. An example for this would be that It still became important, because it means the metal can now access a use where in size and weight matter.

anodized sheet metal can also be molded in many kinds of shapes and forms which is another added advantage to using the material run by.Commentaries It is malleable enough to bend, cut and shaped into virtually any size or configuration. By way of this, it is equally suitable for architectural design (the image was produced by Matt Guetta) as interior and even fine art.

By offering colors and finishes reflective of an assortment, as previously depicted along the color spectrum graph to aid in your selection process - you can add diversity by using this sheet metal fabrication design technique for beautiful accents or decorative pieces. It is an apt tool to personalize the projects of designers and artists. The customizability of the material also drives creative and innovative design.

an anodized sheet metalfocused on exports, ROGOSTEEL has focused over past decade on improving product quality and promoting services. ROGOSTEEL has developed collaborative relationship with over 500 customers across Asia, Europe and South America. company also has earned a reputation for their pragmatic approach integrity.company has been awarded "Shanghai Best Export Enterprise" and China Inspection-Free Products" as well as "Alibaba Outstanding Trade" over a period of time. The client satisfaction rating is 100%.

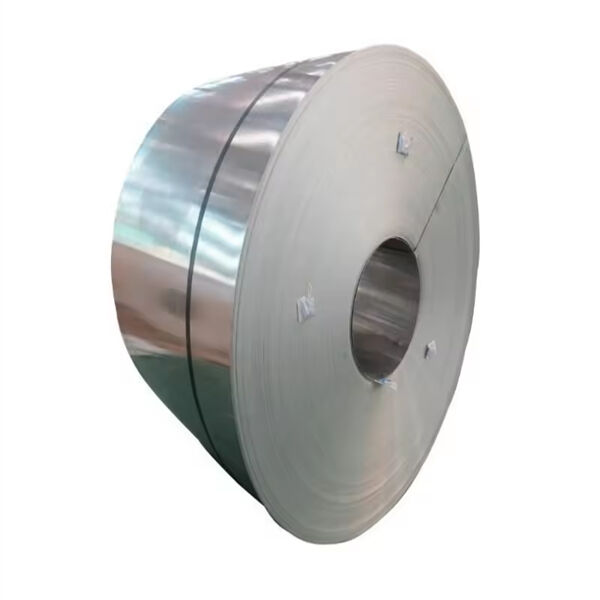

Rogosteel provide wide range products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. Provide customized services: 1825 RAL colors custom-designed colors offered.comes with a range applications and can be used for corrugated anodized sheet metal/glazed tiles/sandwich panel/home appliances/power distribution cabinets/keels.Relevant cases include cities located in Eastern Europe, large domestic airports, Samsung factories South Korea, Hisense refrigerators Africa, government engineering procurement, port construction the Middle East.

Rogosteel certified by SGS/BV. ISO9001, ISO14001, OHSAS18001, OHSAS18001 and ISO14001 quality management systems quality anodized sheet metal. Raw materials for substrates products originate from Tangshan Iron and Steel and HBIS. paints used in the production process are made by internationally-renowned brands such as AKZO and PPG. technology behind the product utilizes high-end production machines that are imported from Germany. also features fully enclosed production workshops strict quality control. The production line is monitored by a professionals from the team quality inspectors, in real-time. The product that is produced is tested with 100% accuracy..We have equipment: zinc layer dynamic monitoring equipment, defect detection Board flattening equipment and UV resistance testing equipment. Warranty period of 15 years.

Rogosteel has nine production lines that have an annual output of 2,000,000 tonnes has made long-term strategic agreements with more than 20 professional logisticians the largest domestic port customs brokers in order to ensure the efficiency cargo shipping. per the customer's specifications national policies we can assist in preparation different testing certification certificates in documents customs clearance for goods delivery, including B.V. certification, CO anodized sheet metalcertification, etc. company has a qualified after-sales department that monitors after-sales service throughout the process. It is available 24 hours a day. Within 12 hours, business will address any after-sales issues and provide initial solutions in 24 hours.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy