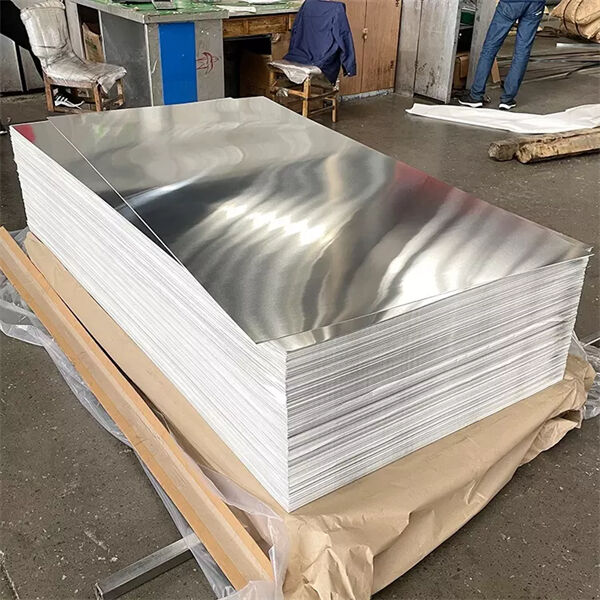

A special kind of metal, an odized aluminum sheetatronoxide is made with a protective layer on the surface. This layer helps it not turn ugly after a while. I like to think of it as putting on sunscreen so you are not burnt by the sun. This protective layer is like sunscreen for avoiding sunburn, but it keeps your metal looking shiny as well. This skin, in addition to being nice looking makes the metal much tougher as well. This makes as it can be used for example in multiple different applications and products anodized aluminum very versatile!

Another great thing about this type of aluminum is that it can come in all different beautiful bright colors. This versatility makes it aesthetically appealing as a fashion material. This is crucial to bear in your mind: whatever said and done, beauty alone does not cut it. The metal is treated with a unique layer that decreases the chances of scratching and rust from forming. These properties enable anodized aluminium sheet metal to last for a long time before it requires replacement. The Rust will allow the to be durable enough for use over many years without problems with wear and tear.

What truly makes anodized aluminum sheet metal arguably the best is its protective layer. Metal is put through an unusual process to make this special layer. Step 1: The metal is placed in a liquid solution. Electricity next passes through this liquid, also assisting in the process of building a layer on the metal's surfaces. And it is like a magic trick, right? It is an extremely thing layer, but it really strong and tough. Anodized aluminum is a tough material, which explains its wide use as well.

The anodized aluminum sheet metal is produced for a lot of reasons to be utilized in many products. Widely used in factories and industries to produce critical components for airplanes, cars or even buildings This is due to the fact that anodized aluminum has a combination of durability and lightweight property allow for easier manipulation. However, it is not limited to working spaces but even used in interior designing. It is also used for creating luxurious sign boards, plaques and even jewelries. It can go with any item of clothing, and the various colors in which it is available make perfect a fashionable accessory.

Anodized Aluminum Sheet Metal Use in Different Industries and Jobs It is very important in the production of parts for airplanes and rockets, e.g., aerospace industry. That is because it can bear heat and harsh conditions. Wheels, engine parts and car body panels in the automotive industry are anodized using aluminum. It is strong and exceedingly resistant to rust, which makes it a good option for such applications. It is found being used operation windows, siding and roofing material in construction. This is because it says the weather and also refuses to stand over a number of years.

What is anodized aluminum sheet metal?It has a variety of uses, it can be used practically and most sought-after for the environmentally conscious people or if you are someone who looks out to reduce cost. The fact that it is recyclable is one of the best things about it. It also means that when it is done being used, instead of ending up in a landfill which can create harm to our earth. It can be recycled and transformed, which would allow consumers to have a positive use of their time. Furthermore, with anodized aluminum being built to last and have a minimal duty cycle in terms of wear-and-tear you would not need purchase fresh metal nearly as often. This will save your money in the long run you exactly know that it does not require exchange soon. And it means less mining and production of metal, which ultimately saves our natural resources.

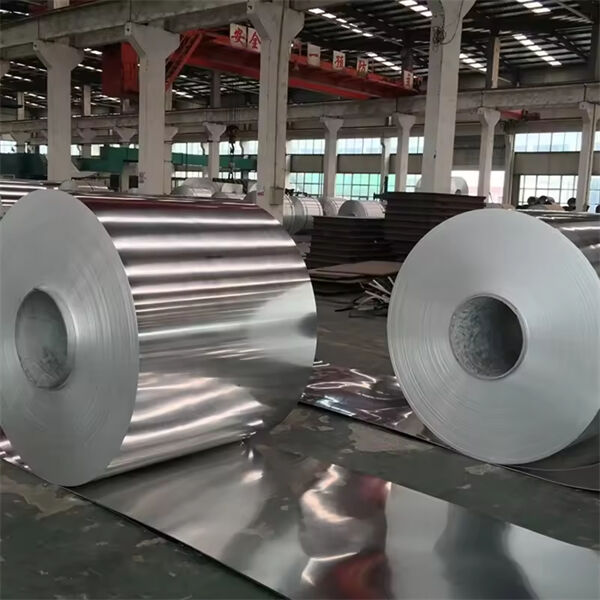

Rogosteel provide a wide range products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. Customized services also available including 1825 colors RAL custom-designed colors customers.This product suitable a wide range of uses that include corrugated board/glazed tiles/sandwich panel, home appliances, power supply cabinets, and keels.Relevant cases include cities in Eastern Europe, large domestic airports, Samsung factories South Korea, Hisense refrigerators in Africa, government engineering anodized aluminum sheet metalas well port construction projects in the Middle East.

an export oriented enterprise, ROGOSTEEL has focused over past decade on enhancing quality its products and improving service. ROGOSTEEL has built a cooperative relationship with more than 500 customers across Asia, Europe and South America. ROGOSTEEL also enjoys an enviable reputation for their practical anodized aluminum sheet metaland integrity.The company was awarded the "Shanghai Best Export Enterprise" and China Inspection-Free Products", and "Alibaba Outstanding Trade" over a period time. Customer's satisfaction reaches 100%.

Rogosteel has nine production lines with an annual output 2,000,000 tons and has made long-term strategic agreements with more than 20 expert logistics agents major domestic customs brokers for ports to ensure the effectiveness shipping cargo. We are able to work with our customers process various testing certificates and certification the document of customs clearance to ensure the delivery their goods. includes the BV certificate, CO Embassy certification, more.company has a professional after-sales anodized aluminum sheet metalthat monitors the after-sales process throughout the process. They are available 24 hours a day. Within 12 hours, the business will respond to any after-sales problems and offer solutions within 24 hours.

Rogosteel a product that has been certified by SGS/BV. ISO9001, ISO14001, OHSAS18001, OHSAS18001 ISO14001 quality management systems. raw materials product substrates are sourced from Tangshan Iron and Steel and HBIS. The paints for the product are made by internationally-renowned brands like AKZO and PPG. technology behind the product utilizes high-end manufacturing equipment that is imported from anodized aluminum sheet metal. facility also has fully enclosed production workshops and rigorous quality control. The production line is overseen by a expertsthe field of quality inspectors in real-time. The product that is produced is tested at 100%.have a variety of instruments, including: board flattening equipment, defect detectors and ultraviolet resistance testing devices. Warranty for 15 years.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy