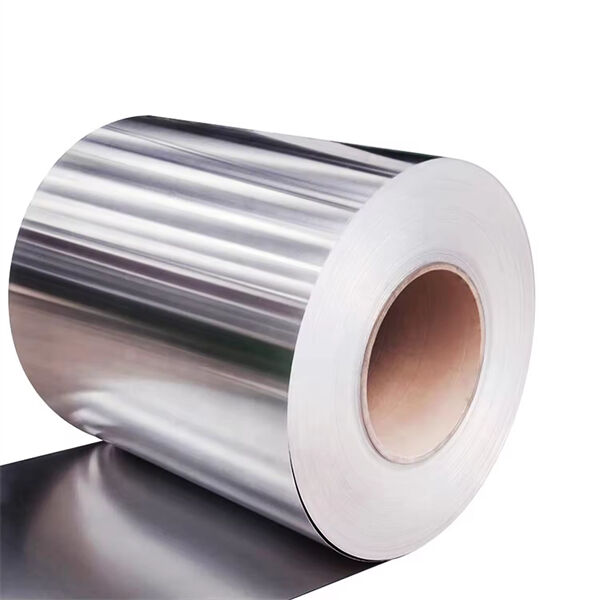

Initially, Allow us describe the light weight aluminum sheet coil. It is constructed out of aluminum alloy, which means it contains multiple metals merged and build to form a robust material. The aluminum is in thin sheets before it gets made into the coils much like a piece of paper. These coils are used to produced hundreds of tough, high-quality goods.

There are a lot of different possibilities when it comes to using aluminum sheet coil. For instance is used mostly in constructing things such as roofs and walls, gutters etc. They are crucial components of the structures that shelter us from elements. It is also widely used to form ordinary products, such as (beverages), pots and pans like a cooking utensil and car parts that make our vehicles move smoothly. Artists utilize aluminum sheet coil to create some of the most beautiful art on the market today.

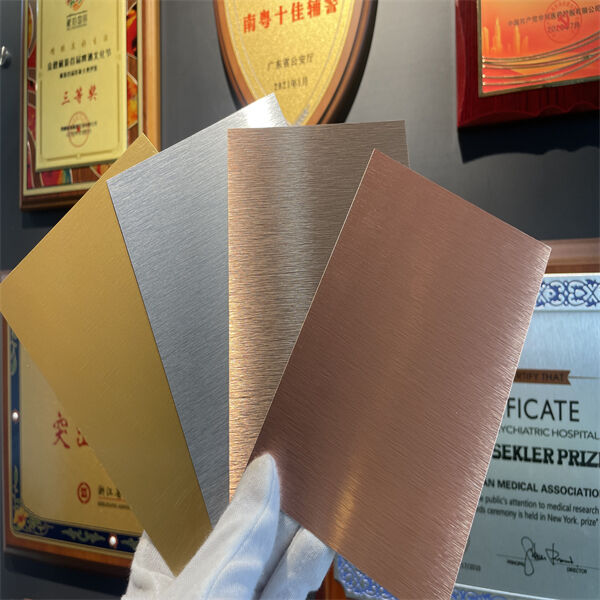

The finish of the aluminum sheet coil is another feature to consider. Finishes like brushed or mirror look quite aesthetically pleasing and are usually used in projects where aesthetics matter. For hoops that are bolted down, other finishes such as Anodized or Paint (in addition to the powdercoated hoop above) can be a lot more practical and often used for building things like bikes, benches or anything else requiring functional durability.

To begin with, they would melt raw aluminum in a super hot furnace. This process is important to melt the state of solid aluminum. The molten aluminum is then poured into a large mold that molds the material as it cools. At this point the aluminum becomes a continuous sheeting that passes through machines to even out its surface. The resulting sheets are wrapped into coils and shipped for applications ranging from construction to manufacturing or artistic expression.

The following are some of the advantages that one can get by using aluminum sheet coil which makes it an ideal choice. One of these advantages is its lightweight so that you can easily carry it and transport. This works really well for those of you who work in the construction field and are required to haul materials around the site. This also makes it very durable, which means that you can use this without damaging or breaking the glasses.

The other advantage to aluminum sheet coil is that it doesn't rust or wear down. It does not degrade when coming into contact with water, so it is a great material for exterior projects such as roofs or walls. They are very durable, and products that are made from aluminum sheet coil can last a long time so it is naturally appealing to anyone who wants their materials to be reliable.

Last but not least, because of this aluminum sheet Coil is friendly to the Earth. Aluminum is very sustainable as a raw material, because it can be recycled countless times without any quality loss. That way, once aluminum products are worn out and no longer needed, they can be melted down for recycling into something else; which in turn helps lessen the amount of waste generated.

In 2013, ROGO INDUSTRIAL (SHANGHAI) CO., LTD. situated in China's economic capital aluminum sheet coil, which an export-oriented company as part of J.X.Y Group. an export-oriented enterprises in last 10 years, ROGOSTEEL focused improving quality of products and promoting service. With the help of its staff, ROGOSTEEL have built cooperative relations with over 500 customers from 100 countries across Asia, Europe, South America, Oceania and Africa have earned a favorable reputation for their honesty and pragmatic way. company was awarded "Shanghai Best Export Enterprise" China Inspection-Free Products" as well as "Alibaba Outstanding Trade" several years a row. Customer's satisfaction reaches 100%.

Rogosteel has been certified by ISO9001 Quality Management System, ISO14001 environmental management system OHSAS18001 occupational safety health management system, SGS/BV as well as other certifications. The raw materials for product substrates come from Tangshan Iron and Steel and HBIS. The paints used in the production process are manufactured by internationally recognized brands such as AKZO and PPG. The technology used in the product is top-of-the-line production lines imported from Germany, fully enclosed production areas, rigorous quality control. production line monitored by professionals from team of aluminum sheet coilinspectors in real-time. finished product checked with 100% accuracy.. offer instruments like Zynth layer dynamic monitoring equipment, defects detectors boards flattening equipment and ultraviolet resistance testing equipment. Warranty of 15 years.

Rogosteel provide wide range products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. Provide customized services: 1825 RAL colors custom-designed colors offered.comes with a range applications and can be used for corrugated aluminum sheet coil/glazed tiles/sandwich panel/home appliances/power distribution cabinets/keels.Relevant cases include cities located in Eastern Europe, large domestic airports, Samsung factories South Korea, Hisense refrigerators Africa, government engineering procurement, port construction the Middle East.

Rogosteel's nine production lines that produce annual output that exceeds 2,000,000 tons have also established long-term strategic agreements more than 20 professional logistic agents a the largest customs broker for ports in the country to ensure the efficiency shipping cargo. Based on national policy requirements can collaborate with processing of various tests and certification certificates in documentation for customs clearance of goods delivery, including the BV aluminum sheet coil, CO embassy certification, etc. professional team of after-sales experts is available throughout the day, all year round to ensure the service is being monitored. After-sales issues will be addressed within 12 hours and initial solutions are provided within 24 hours.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy